Service and Parts manual (Version B)

58

Wireless

3.

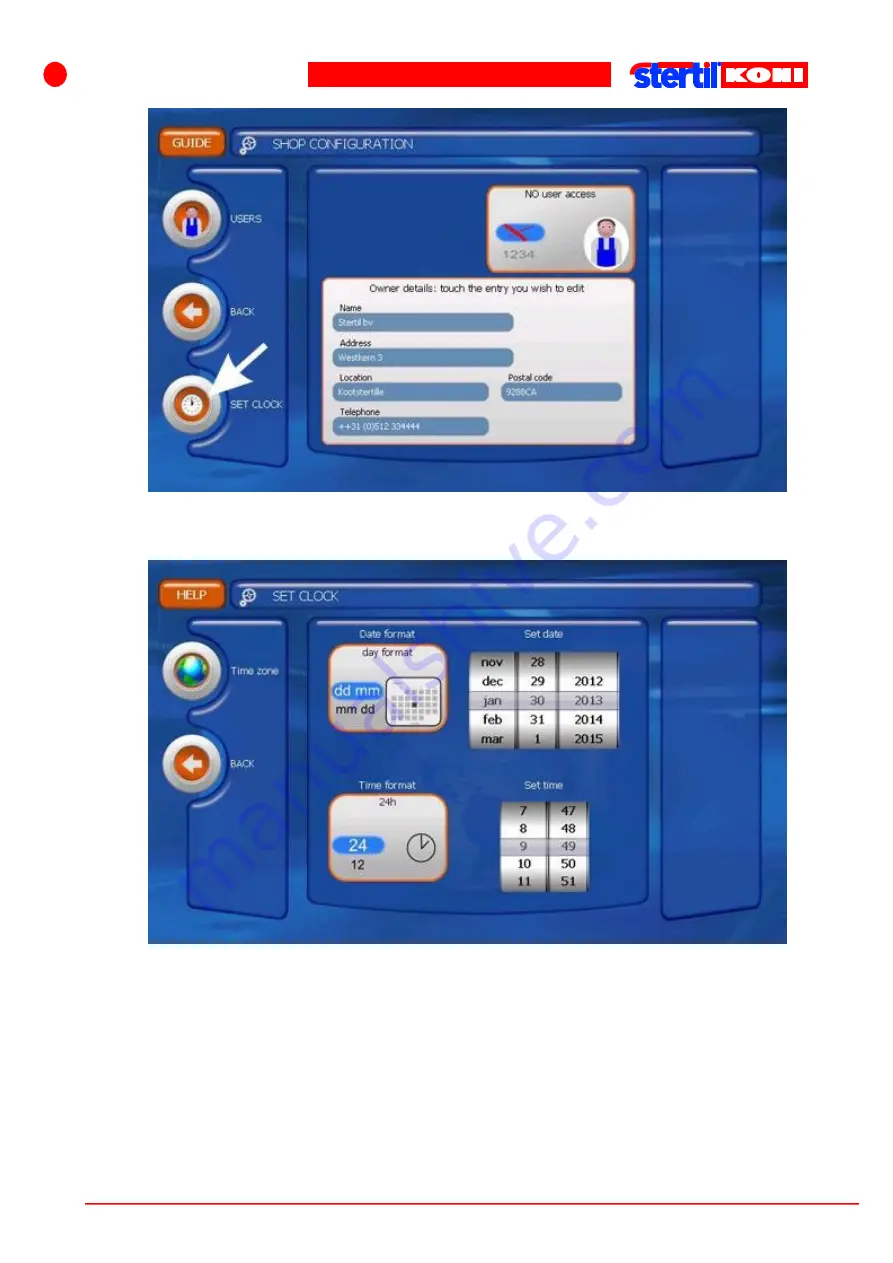

Press the [SET CLOCK] button in the shop configuration screen.

The screen for setting the clock time appears.

4.

Select the desired display format for the date and time.

5.

Set the correct date and time.

6.

Press the [TIME ZONE] button.

The screen for setting the correct time zone appears.

Summary of Contents for ST 1065-FWF

Page 1: ...Mobile column lifts Wireless Service and Parts manual 2015 Stertil B V 38007815 B ...

Page 109: ...Service and Parts manual Version B 109 Wireless 8 18 Hydraulic cylinder ST1075 ...

Page 111: ...Service and Parts manual Version B 111 Wireless 8 19 Hydraulic cylinder ST1065 ST1085 ST1100 ...