29

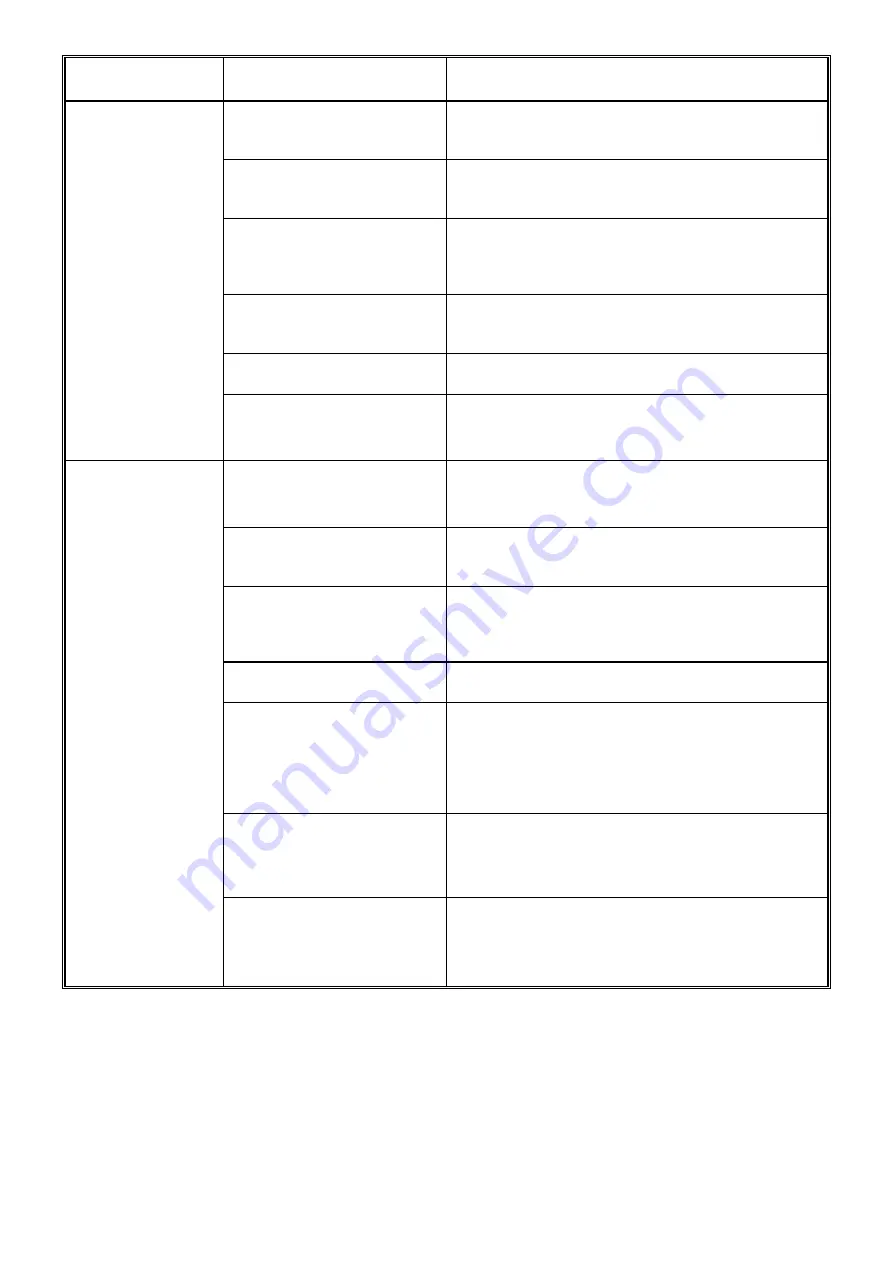

FAULT

POSSIBLE CASE

REMEDY

No battery power.

Check main fuse above batteries inside cover. Have

batteries tested by qualified battery supplier

Oil level too low.

Add oil as necessary, refer to lubricating instructions on

lifting column.

Air in hydraulic pump (only

possible after the tank has been

empty).

Press the

⇑

(UP) and SET REF buttons until the lifting

column rises (max. 1 minute).

Safety valve not properly

adjusted

Have valve adjusted, contact Service Department to

check the valve.

Pump has insufficient yield.

Replace the pump.

Column does not lift.

Maximum height difference

(more than 2 1/2") exceeded.

Hold “SET REF” button for 2 sec until control light is on.

If the defect occurs again, contact the service department.

No battery power.

Check main fuse above batteries inside cover. Have

batteries tested by qualified battery supplier

Catching pawl not disengaged

from locking system.

Raise column approximately 2" and then lower.

The electrically operated

lowering valve on the hydraulic

unit does not open.

No mains power for solenoid or lowering valve is faulty.

Have fault corrected by the Service Department.

Dirty lowering valve.

Have valve cleaned or replaced by service department.

Maximum height difference

(more than 1 1/4") exceeded.

Press lifting button until the height difference has been

cancelled out. If lifting is not desired, the "SET REF" button

can be pressed once. Following, lowering can be activated.

The difference of 1 1/4" will be maintained.

If the defect occurs again, contact the service department.

Maximum height difference

(more than 2 1/2") exceeded.

Hold “SET REF” button for 2 sec until control light is on.

If the defect occurs again, contact the service department.

Column does not

lower.

Highest position stop practically

nearly equal to highest locking

position stop.

Slightly raise the ramp by touching S2. Then set highest

position stop (see fig. 8.1)

Summary of Contents for ST 1082-F/BAT

Page 1: ...Mobile Column Lifts ST 1082 F BAT ST 1082 R BAT Installation operation service 32738980 A ...

Page 2: ......

Page 14: ...10 ...

Page 31: ...27 MICROPROCESSOR BOARD Fig 8 1 Location of fault indication LED s ...

Page 37: ...33 FIG A ...

Page 39: ...35 FIG B Item 6 locked with loctite 542 sealant ...

Page 42: ...38 FIG E CONTROL BOX ...

Page 44: ...40 FIG F SCHEMATIC DIAGRAM ...

Page 51: ......