Final Assembly Continued

☐

Use a 5/64” hex driver to secure motor mount

to hull using 7 of the provided #2 x 3/8”

socket head screws. Set screws to just snug

mount to gasket surface then apply only 1/2

turn to each screw to mildly compress gasket.

☐

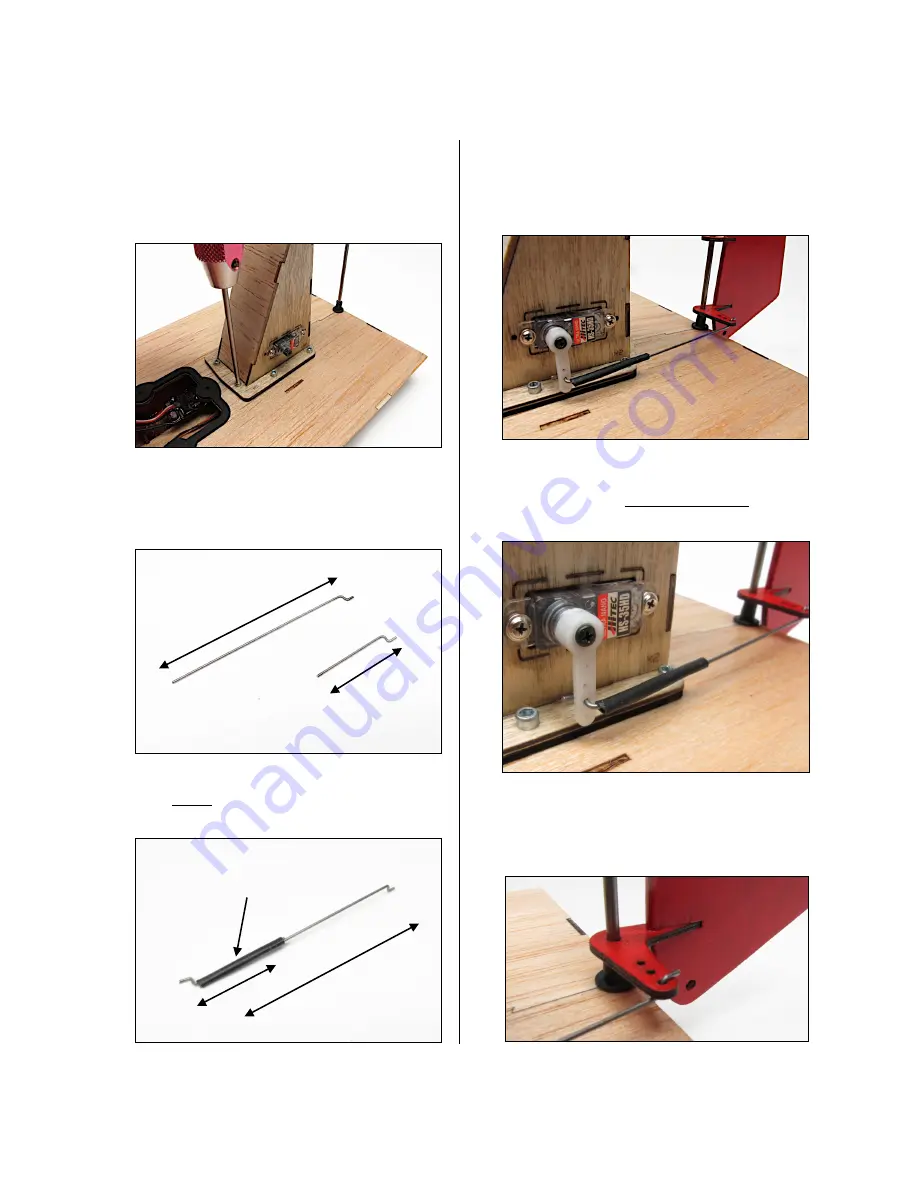

Create the Rudder Control Rod, cut the

provided 1/32” diameter wire into two lengths

1” and 2-3/4”. Now, using small needle nose

pliers, bend a “Z” in one end of each length.

Join the these lengths of wire by overlapping

each

within

a 1” length of heat shrink. Shrink

the tubing with a heat gun to retain parts.

☐

Trim your servo control horn so that when

installed as illustrated it will not drag along the

hull of the boat. Mount the control rod to one

of the outer most holes on both the servo and

the rudder control horns.

With the HS-35HD servo we prefer to use the

long horn, trimmed as illustrated, with the

control rod in the 3rd or 4th hole out from the

servo center.

At the ruder end of the control rod we prefer

the “Z” bend to enter from the bottom as

shown as this nets the best clearance from

the propeller.

Build Instructions

© 2013 Stevens AeroModel all rights reserved.

Page 18 of 25

2-3/4”

1”

1”

2-3/4”

1” Length Heat Shrink