12. Ok I know you have been itching to glue the ribs to the spar. Lay the wing up-right on your building board. Add

some weights to flatten the assembly (assuming it is not already flat). Key the 3/32” turbulators to the wing

assembly. With the wing flat upon your building surface go ahead and wick thin CA into the turbulator-rib joints,

spar-cap strip joints, and spar-rib joints. Allow the assembly ample time to dry before removing weights.

Minor warping may be removed with covering. If, for some reason, you come up with a severely warped wing –

wet the wing with glass cleaner then re-apply weights. Allow assembly to dry for 24 hours (this should relax the

wood and remove any warps).

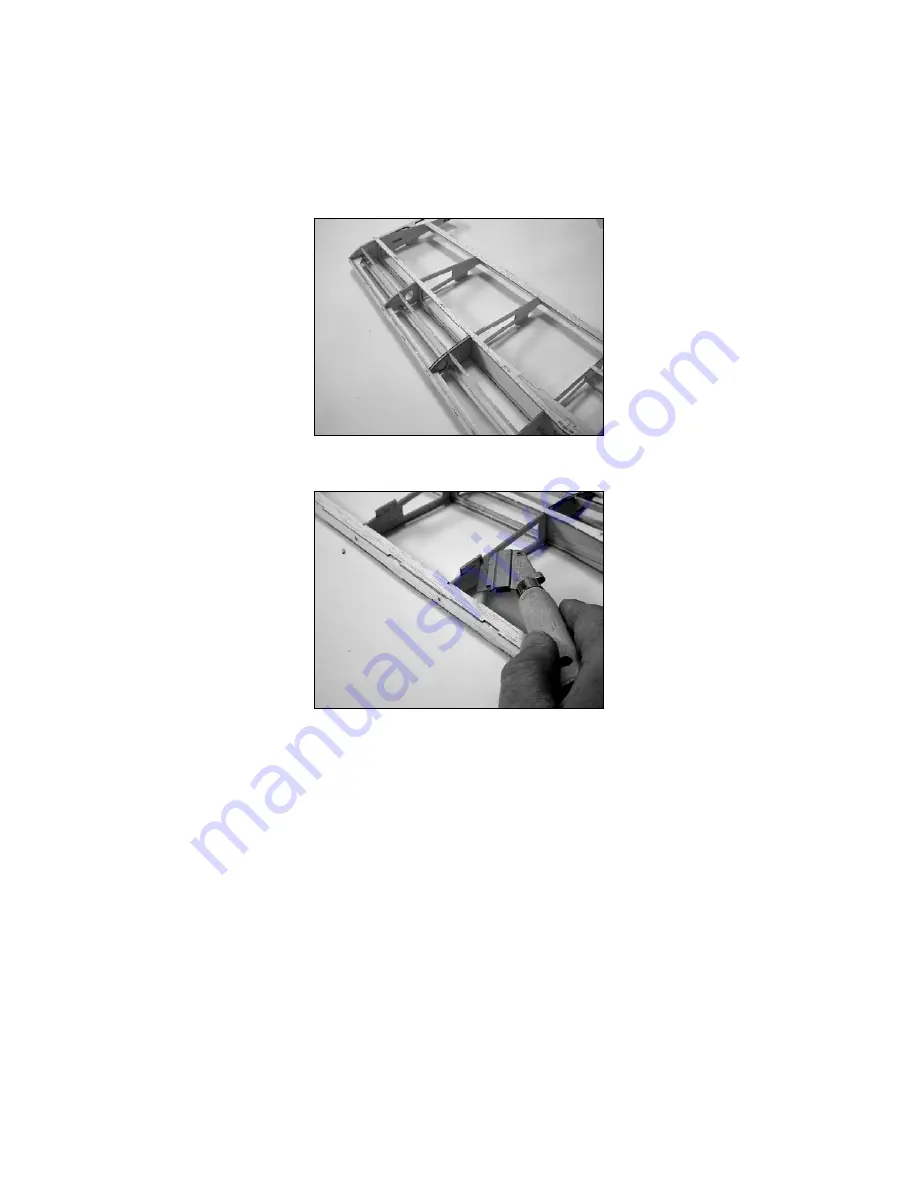

13. Remove the wing riser jigs with a sharp razor blade.

14. Final sand the wing round out the spar cap stripping to follow the contour of the wing ribs. Round the leading

edge and test fit the wing to the fuselage – remove all high spots that prevent the wing from fitting within the

fuselage. Slowly work the wing and do not force parts to fit.

© 2003 Stevens AeroModel.

Page 16 of 20