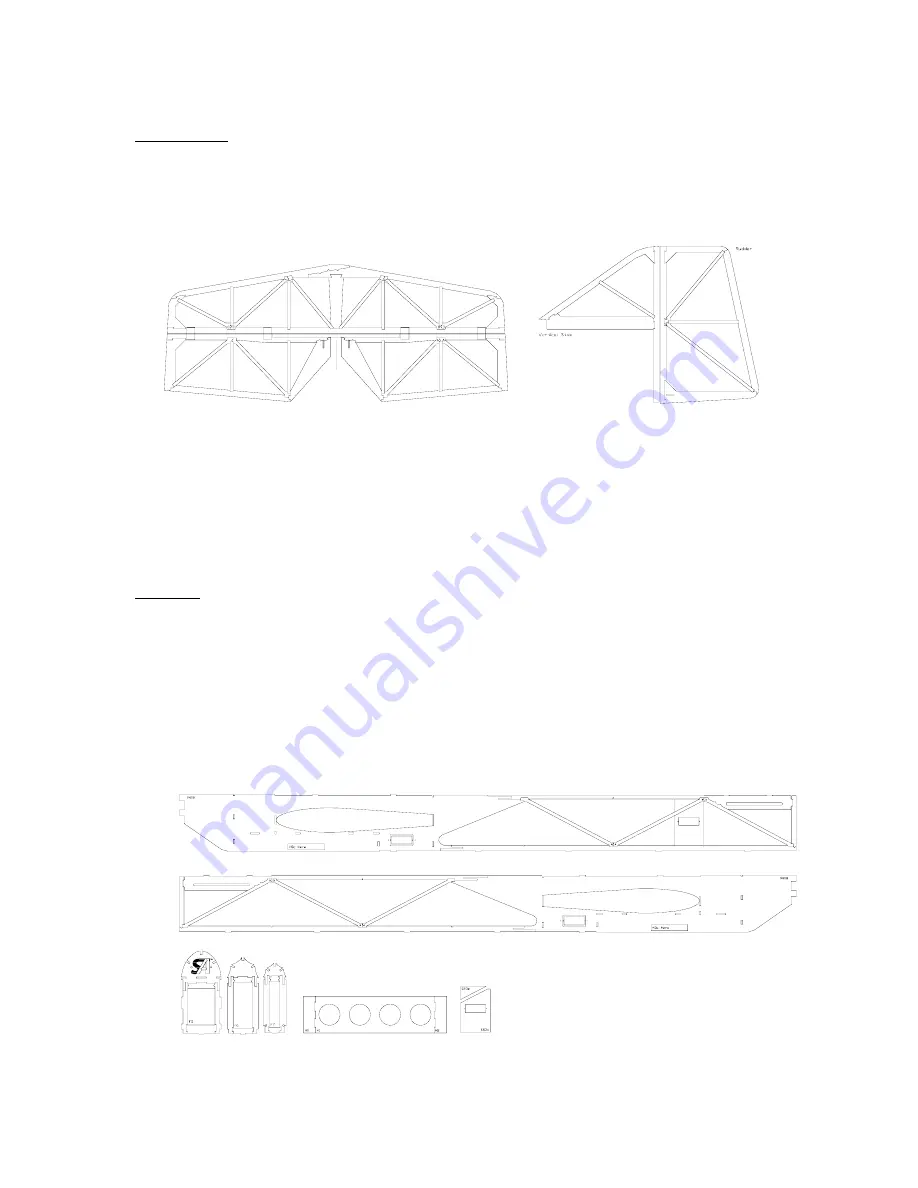

Tail Feathers

Build the Rudder, Vertical Stabilizer, Elevator, and Horizontal Stabilizer. Parts are grouped according to tail section

component on the 3/32” balsa sheets. Work with each component separately. Assemble over plan sheet, removing only

those parts necessary to complete each individual component. Start each assembly by building up the outside edges

(just like a puzzle) – finish by inserting center truss parts. Though the parts fall together and self jig, pay particular

attention orientation and making solid glue joints.

3/32"x4"

Alum. Tube

Elevator

1.

Elevator Joining Tube. Verify that the provided 3/32” aluminum tube is of the appropriate length and rough the

surface with fine grit sand paper to remove dirt, oil, and debris, from the tube. Wipe tube with rubbing alcohol,

then, Using thin CA, tack the joining tube to each elevator halve and allow to dry. Once dry use a small amount

of 5-minute epoxy to create a fillet between the wood and the aluminum tube.

2.

Sand all surfaces with fine grit sand paper, rounding leading edge pieces while leaving trailing edge parts

square, in preparation for your preferred hinging method (Centered CA Hinging is Recommended).

Fuselage

Fuselage components are exceptionally brittle until the entire assembly is complete – this is especially true aft of the wing

saddle. Handle parts accordingly and

do not force the fit! Do not glue a part until instructed to do so – failure to

follow this simple instruction may result in a break down of the space time continuum

or may result in a fuselage

that is not square and true. To date no one has failed to follow this instruction so the consequences outlined above are

but pure speculation.

1.

Let’s assemble the major fuselage components. Assemble Fuselage sides and formers F5, F6, F7, and H1/H2.

Align parts with rolled plan sheet and wick CA into joints. Note that each fuselage side has a side marked

“inside” also note the detail on the plan sheet for installing the elevator servo SR3a/3b block to one fuselage

side.

© 2003 Stevens AeroModel.

Page 5 of 20