10

Stewart Filmscreen

INSTALLATION PROCEDURES (CONTINUED)

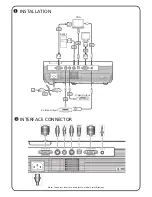

ELECTRICAL CONNECTION

The unit requires standard AC input (unless an alternate voltage has been specified)

i

i

CAUTION

Professional techniques need to used when making any electrical connection A qualified electrician

should perform these procedures

Be sure to follow all standard safety procedures for installing electrical devices

Do not disassemble or alter the configuration of the motor or the unit’s electrical connections This

may cause injury to you or damage to the product The electrical connection should be made only

to the type of power source indicated on the marking label

Stewart Filmscreen supplies a short electrical connection wire that is fitted with a Molex motor connector

Connect the harness (pigtail) to the incoming AC Romex or service cord by wire nuts

1 Feed the incoming AC Romex or service cord through the Romex connector on the housing

2 Connect the pigtail with wire nuts on the inside of the housing The AC connection to this pigtail

should never be made on the outside of the enclosure as this would violate NEC electrical code

and UL standards

WARNING!

Make sure the motor leads do not get pinched between the end plate and housing once the screen

/ bezel has been installed Should this occur the motor will short causing failure

CONNECTING THE CONTROL SYSTEM

Visionary Medio is provided with an IMC (Intelligent Motor Controller) as a standard control system The

IMC supports:

`

Screen Trigger Interface

`

Dry contact closures for use with a low-voltage wall switch or home automation controller

`

Stewart 3-button wall pad with infrared sensor and handheld IR transmitter RS-232 via IBT100 Serial

Translator

Note: Other control systems are optional All control systems for the Visionary Medio are to be connected

in an outboard fashion No internal controllers are available