stewmac.com

finishing, now is the time for that step (see “Install the tailgut

saddle”).

Traditionally, the color of the violin covers the peghead and

heel of the neck, but feathers away to an almost-bare playing

surface on the back of the neck. By sanding and scraping,

feather the finish at the heel and peghead creating a quick,

smooth transition blend from the finish to bare wood.

Scrape and sand the maple smooth, then add a light stain

for a traditional look. Practice on a scrap piece of maple

to find the color you want. We used ColorTone Amber and

Medium Brown, in tiny amounts, added to Behkol solvent

until we got the look we liked.

Then we stained the real thing. Allow the stain to dry, then

rub the neck with a clean rag to burnish it. Wipe on a coat or

two of Tung Oil for a final finish that has a bare wood feel.

Remove the mask from the mortise you cut for the saddle.

A little careful cleanup will probably be needed. Glue the

saddle in place. If you chose to cut and fit the saddle after

�

�

�

�

����������

���������

����������

Re-install the tailgut saddle

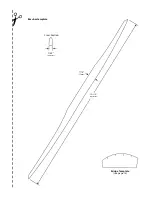

The pegholes are tapered to accept the tuning pegs, but

you’ll need to refine this shape with a violin peg reamer for

a good fit. A few careful turns should be all that’s needed.

Check the fit after every twist of the reamer. The

diagram

shows that the band around the tapered shaft is generally

1/2" (12 to 14 mm) from the side of the pegbox. Try to make

all four pegs extend the same distance.

When each peg is properly seated and operating smoothly,

mark the ends of the pegs with a pencil to show where

the excess wood needs to be cut away. Remove the pegs

and trim them to length, then smooth the cut ends with

sandpaper.

Put the trimmed pegs back in their respective holes, and

mark the location of the string hole in each peg. The string

hole should be slightly off-center (as measured within the

pegbox), toward the knob side of each peg. Use an awl to

make a start for the hole to be drilled.

Carefully drill a 1/16" (1.5mm) hole through each peg, then

smooth the sharp edges of the hole, for less stress on the

string. When drilling, hold the peg down firmly on a hard

wood surface so that when the drill bit comes through the

other side it doesn’t “blow-out” wood.

Fit the tuning pegs

Final-finish the neck

14

Summary of Contents for 5342

Page 1: ...Violin Kit 5342 Assembly Instructions www stewmac com ...

Page 2: ......

Page 9: ... ...

Page 10: ......

Page 23: ......