Z001007/0_4_September 2007

Page FUEL SYSTEM-5

FUEL SYSTEM

INSTALLATION INSTRUCTION

7. 3. MATERIALS

If possible, the fuel tanks should be made of stainless steel (Nirosta) . Light metal, steel plate or plastic may be

used too.

Copper plate, galvanized or pot-galvanized plate are no suitable materials for fuel tanks.

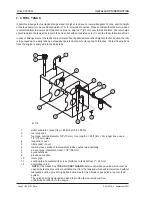

7. 4. TWIN FUEL TANKS

For a lateral arrangement of the tanks in the boat, a construction acc. to ill. 7/3 may be chosen.

Connect the tanks on top and on bottom with pipe lines equipped with stop cocks. Min. inside diameter of the

lower connecting pipe should be 3/4" (19 mm) in order to permit a filling of the tanks, if they are installed alongside,

from both sides of the boat.

The fuel pipe from the engine has to depart from the lower connecting pipe of the tank (only valid for tanks with

bottom drain). An additional fuel filter or water separator is to be installed in front of the feed pump on the injection

pump.

In case of a daily tank, it is recommended to connect the fuel return pipe to this tank which reduces the filling

intervals.

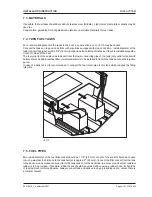

7. 5. FUEL PIPES

Min. inside diameter of the fuel filler socket should be 1 1/2" (38 mm). Length of the socket should be chosen

in such a way that the distance to the tank bottom is approx. 2" (50 mm). Connect the filler socket from the tank

to the deck union by means of a pipe joint to the tank socket. On the deck lead-in a sleeve made of fuel-resistant

rubber is to be provided. If possible, rubber hoses should be avoided. When using a rubber hose, it should be

of fuel-resistant, reinforced quality. Always connect tank and deck union by a grounding cable, unless there is

a metallic contact.

ill. 7/3