. . . . .

R

I

N S T A L L A T I O N

Operation of Air Equalization Valve

SCIENTIFIC TECHNOLOGIES INC.

Call: 1/888/510-4357 in USA and Canada

Universal Safety Mat UM Series Rev. C

© STI 08/2000

15

6 . 2 . O

P E R A T I O N

O F

A

I R

E

Q U A L I Z A T I O N

V

A L V E

6.2.1

P

URPOSE

To allow Safety Mat to equalize with outside atmosphere pressure to insure proper mate operation.

6.2.2

U

SE

After mats have been properly installed, clear any debris from area around air equalization valve.

Open the air equalization valve with a standard screw driver by turning the air equalization valve

screw 1 1/2 turns counter clockwise.

Do not remove screw.

Allow the air equalization valve to remain open for a minimum of 30 seconds.

Do not stand on or

allow objects

to be on the safety mat during this process.

After the mat has been equalized, close the air equalization valve by turning the air equalization

valve screw clockwise until securely closed.

Do not over tighten

.

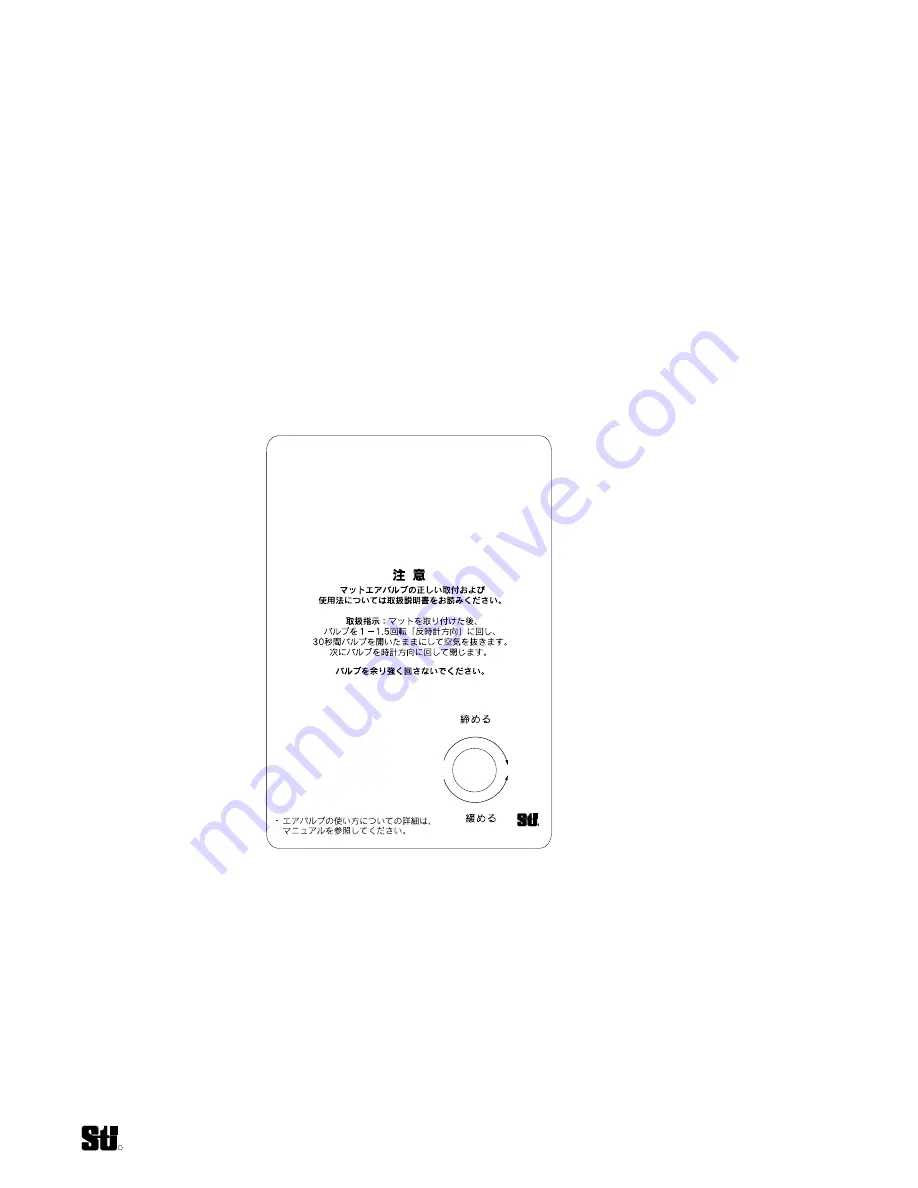

Figure 6-6 Air Valve Instruction

R

T I G H T E N

L O O S E N

L a b e l P / N 2 8 6 0 7 - 0 0 1 0 R e v. A

-

Please refer to manual for detailed instruction

on how to use the air valve.

- Consulter le manuel pour tous renseigne-

ments concernant le fonctionnement de

la soupape pneumatique.

- Sírvase consultar el manual donde se

detallan las instrucciones sobre cómo

hacer funcionar la válvula de aire.

- Fare riferimento al manuale per

istruzioni dettagliate in merito al

funzionamento della valvola dell’aria.

- Ausführliche Hinweise zur Bedienung

des Luftventils sind der entsprechenden

Gebrauchsanweisung zu entnehmen.

IMPORTANT NOTICE

Read instruction manual for proper installation

methods and operation of air valve.

Instruction:

After mat is installed open air valve

by rotating valve "counter clockwise" 1 1/2 revolutions,

let mat sit with valve open 30 seconds.

Close valve by rotating clockwise.

Do not over-torque valve.