17 West St., W. Hatfi eld, MA 01088

|

800.582.8423

|

413.247.3380

|

fax 413.247.3369

|

info@stiebel-eltron-usa.com

|

www.stiebel-eltron-usa.com

Simply the Best

INSTALLATION INSTRUCTIONS

SOL 27 PREMIUM S & W COLLECTORS - 230016 & 230017

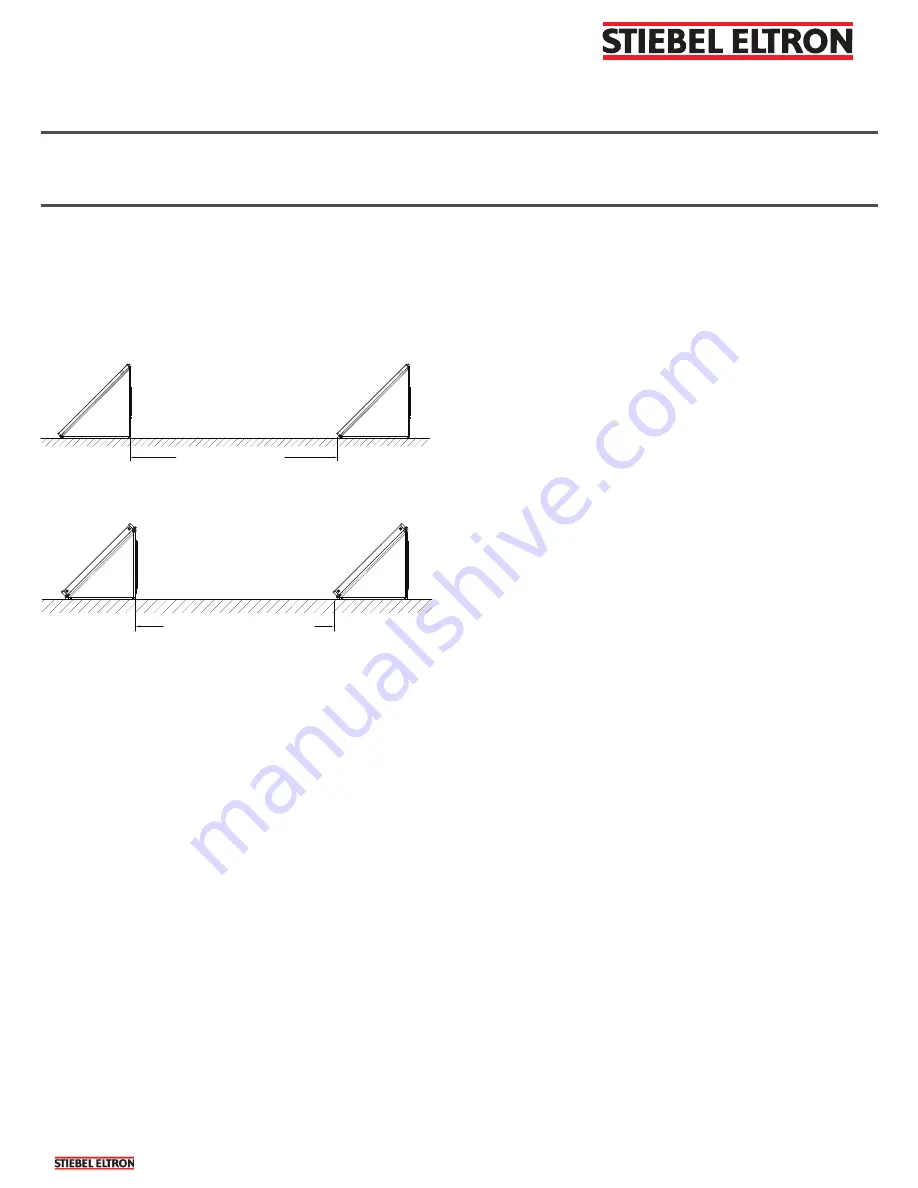

Collector Spacing

For latitudes up to 50°, use the following distances for

mounting solar arrays behind each other. For higher

latitudes, it may not be practical at all to orient solar arrays

behind each other because of the low sun angle.

At least 25 ft. (7.6 m)

Array spacing for 45° Vertical Mounting

on a flat roof or ground.

At least 14 ft. (4.0 m)

Array spacing for 45° Horizontal Mounting

on a flat roof or ground.

6 Commissioning the System

6.1 Pressure and Leak Test

After the pipe work has been installed and the collectors

have been connected it will be necessary to pressure-test

the system to detect leaks before fi lling the solar loop with

heat transfer fl uid. Propylene glycol solutions can leak

from much smaller gaps than can water; so such testing is

critical to assuring a successful installation. Recommended

test pressure is 80 psi. Thermal pipe insulation should

be installed only after the leak test has been successfully

completed.

It is recommended that compressed air be used to test the

system for leaks, as it is very easy to make repairs and it will

prevent loss of solar medium, spills, property damage, and

messy clean-up problems. Air is also capable of revealing

very small leaks, that water may not reveal, through which

propylene glycol will often leak. Leaks will be evident from

the sound of escaping air, observation of bubbles emanating

from fi ttings and other leak-prone components that are

coated with soapy water, and watching the pressure gauge

over time. Bear in mind that the pressure gauge will vary

some based on temperature of the air, so one must try to

read the pressure at nights when the system cools down to

ambient temperature or when covered.

6.2 Setting the Expansion Tank Pre-charge Pressure

While the leak testing is being performed, the installer

should set the expansion tank’s pre-charge pressure.

Make sure that the “wet” side of the expansion tank (pipe

connection) is vented to atmosphere. Using a compressor,

pre-charge the tank with air (or use pressurized nitrogen) to

a fi nal pressure of 5 psi less than the target system pressure.

For example, if the fi nal target system (solar loop) pressure

is to be 50 psig, fi ll the expansion tank to 45 psig (which is

the recommended default value). When complete, cap the

Schrader valve fi tting and re-attach the tank to the pump

station. Make sure the expansion tank always faces up (the

Schrader valve must be pointed down).

6.3 Final Charging & Venting

The solar heating system must be fi lled exclusively with the

premixed propylene glycol heat transfer medium. Stiebel

Eltron glycol containers have been premixed and require no

further treatment. Never mix water with the heat transfer

fl uid, otherwise the essential characteristics and corrosion

protection can no longer be guaranteed. The system must

not be topped off with water.

More Information

For more detailed instructions on how to fi ll, fl ush & charge

the solar loop, consult the pump station manual.

7 Maintenance & Care

Specialists should carry out an annual inspection of the

solar heating system to ensure proper functioning of the

system and its components, including the control unit, safety

equipment, and tank. System components (fi ttings, thermal

insulation, mounting hardware, fasteners, etc.) exposed