iNSTallaTiON

preparations

6

| HSBB 200 S (GB) www.stiebel-eltron.com

10. Preparations

10.1 Installation site

!

Material losses

Never install the appliance in wet rooms.

Install the appliance near the draw-off point in a dry room free

from the risk of frost. To reduce line losses, keep the distance short

between the appliance and the heat pump.

Ensure the floor has sufficient load-bearing capacity and evenness

(for weight, see chapter "Specification / Data table").

The room must not be subject to a risk of explosions arising from

dust, gases or vapours.

If you are installing the appliance in a boiler room together with

other heating equipment, ensure that the operation of other heat-

ing equipment will not be impaired.

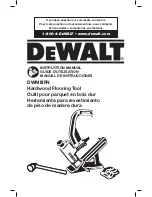

Minimum clearances

≥250

≥400

≥800

≥100

≥500

≥100

≥500

D

00000

70

86

4

The minimum side clearances can be swapped to left or right.

10.2 Transport and handling

!

Material losses

Store and transport the appliance at temperatures be-

tween -20 °C to +60 °C.

Handling

If possible, transport the appliance to the installation site on the

non-returnable pallet. Alternatively, transport the appliance using

a sack truck, creeper board or tension belt, which can be posi-

tioned around the front adjustable feet as a carrying strap.

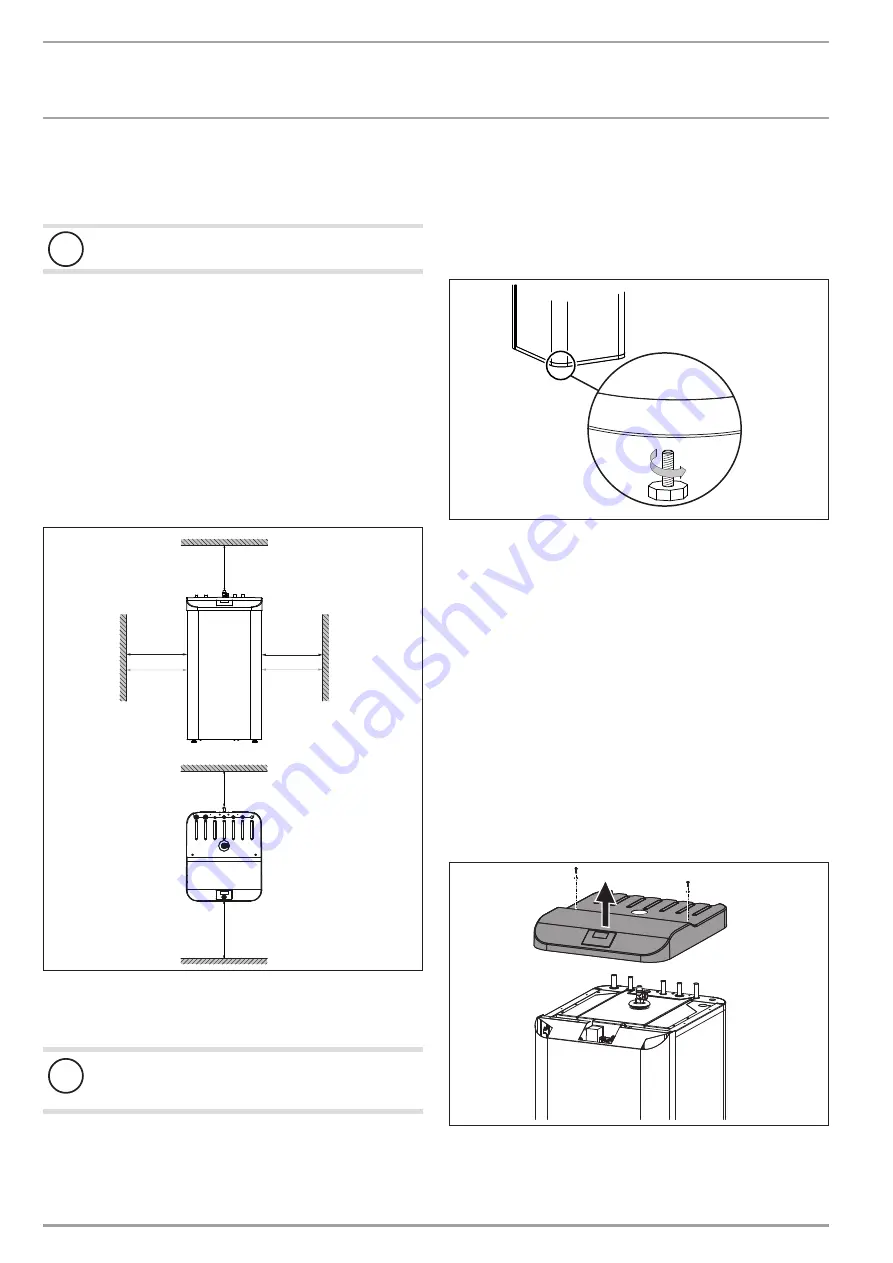

f

f

Undo the 4 screws from the non-returnable pallet.

D

00000

55

51

9

f

f

Tilt the appliance and wind the 4 adjustable feet into the

appliance.

f

f

Lift the appliance off the pallet. For a better hold dur-

ing transport, use the recessed grips on the rear of the

appliance.

11. Installation

11.1 Positioning the equipment

f

f

When positioning the appliance, observe minimum clearanc-

es (see chapter "Preparations / Installation site").

f

f

Use the adjustable feet to compensate for any unevenness in

the floor.

11.2 Removing / fitting the front casing

When removing the cover, take care with the cable connections

between the appliance and the electronic operating assembly.

D

00000

70

87

9

f

f

Remove the 2 screws on the cover.

f

f

Lift the cover.