INSTALLATION

Technical data

12

| SOL 29 Premium

www.stiebel-eltron-usa.com

9. Technical

data

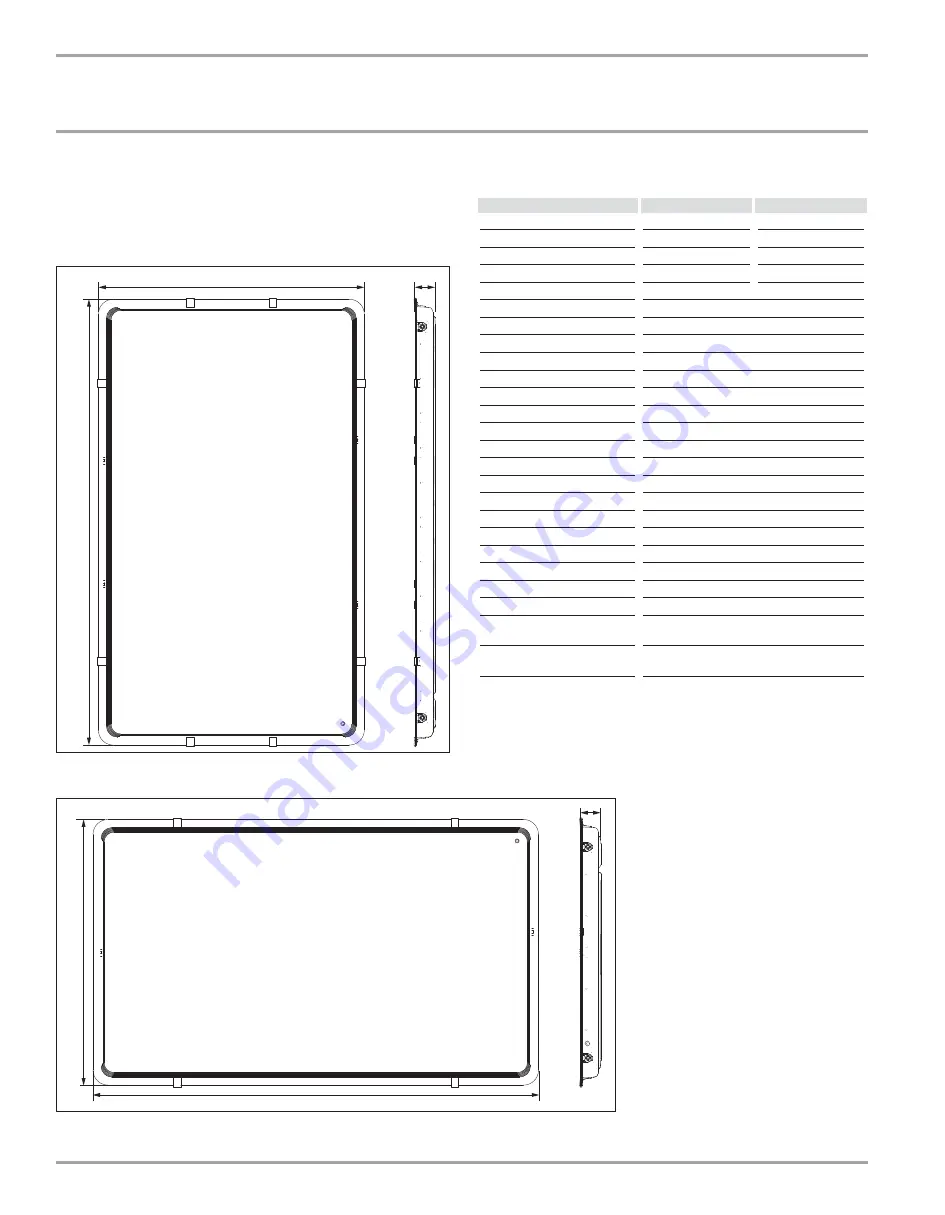

9.1 Dimensions

SOL 29 Premium S

A

B

C

SOL 29 Premium W

A

B

C

9.2 Data

table

SOL 29 Premium S SOL 29 Premium W

Item Number

290016

290017

Type

Standard / Vertical

Wide / Horizontal

Height (A)

82˝ / 2083 mm

49˝ / 1245 mm

Width (B)

49˝ / 1245 mm

82˝ / 2083 mm

Depth (C)

3¾˝ / 95 mm

Weight

84 lbs / 38.1 kg

Housing material

deep-drawn aluminum tray

Glass cover

Tempered solar safety glass

Glass thickness

1

/

8

˝ / 3 mm

Glass transmittance

>89%

Thermal insulation

2˝ / 50.8 mm mineral wool

Collector connection

1˝ BSPP thread (ships with ¾˝ adapters)

Max. idle temperature

345°F / 174°C

Min. operating pressure

145 psi / 10 bar

Test medium

50/50 propylene glycol/water mixture

Fluid capacity

0.4 gal / 1.5 l

Angle of inclination

15°-90°

Total area

27.66 ft² / 2.57m²

Aperture area

24.33 ft² / 2.26m²

Absorber area

24.65 ft² / 2.29m²

Absorber material

selectively coated aluminum

Absorption level α

95%

Emission level ε

5%

SRCC OG-100 High Radiation C

Rating

30,600 Btu/panel/day /

8.97 kWh/panel/day

SRCC OG-100 Medium Radiation

D Rating

12,100 Btu/panel/day

3.55 kWh/panel/day