INSTALLATION

Installation

EN

GL

ISH

www.stiebel-eltron-usa.com

SOL 29 Premium |

9

3

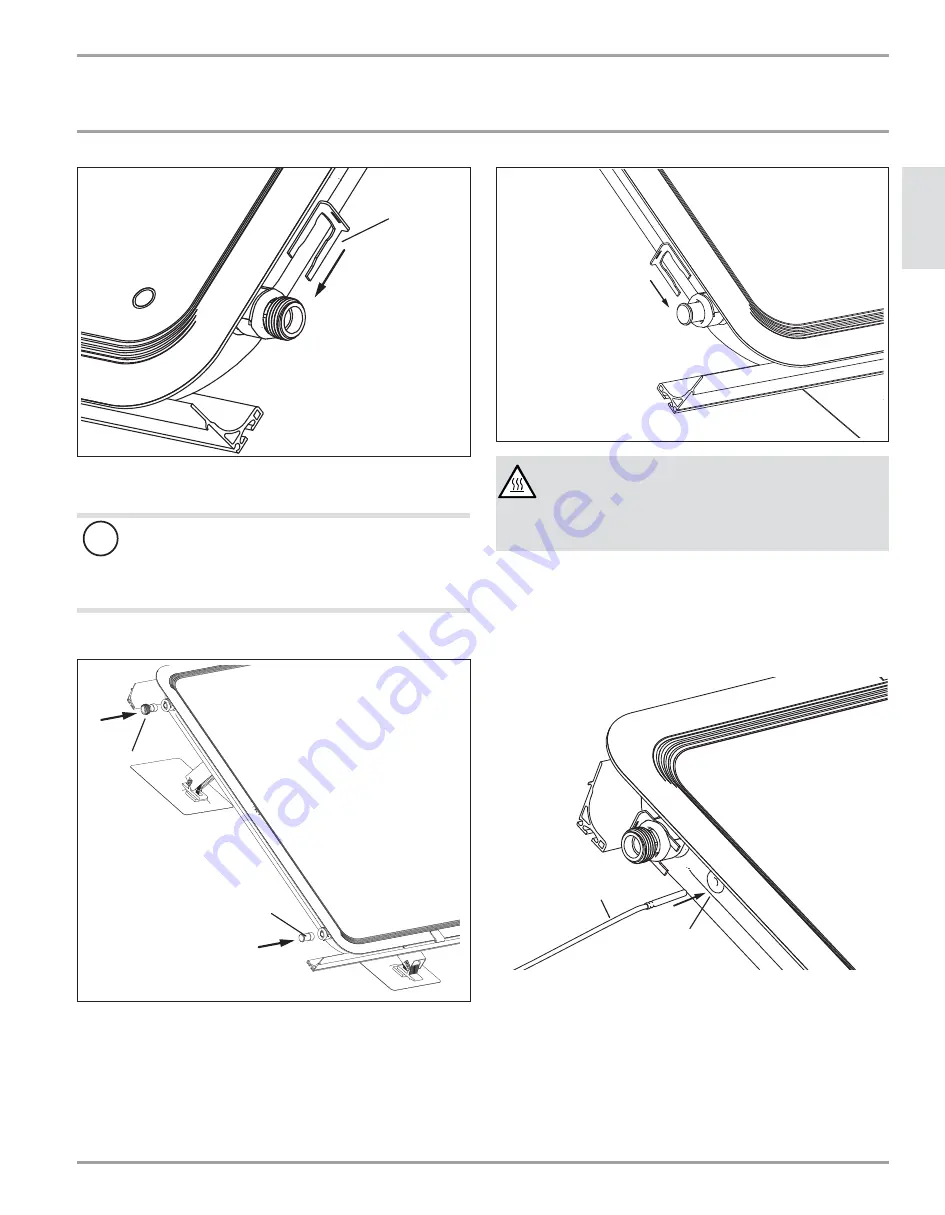

3 Collector connection clip

Secure all external connectors with the collector connection clip.

!

Material losses:

All external connectors must be secured with a collector

connection clip. Failure to do so will cause rapid depres-

surization of the solar loop during the charging procedure

and require repair and reconnection of the connectors.

Hot outlet

4

5

4 1˝ male connector

5 Plug connector

On the connection side where the hot fl uid exits the collector array,

install a threaded connector in the top collector connection and a

plug connector in the bottom collector connection.

WARNING:

Burns

Once the collectors are installed, they will begin to heat

up even during cloudy days. Covering the collectors with

an opaque material will make working around and with

the collectors easier during the installation.

6.9

Temperature sensor installation

Install a temperature sensor into the sensor well of the collector

where the fl uid exits the array and returns to the system heat exch-

anger. Secure the temperature sensor so that it will not become

dislodged from the sensor well accidentally.

2

1

1 Temperature sensor

2 Sensor well