INSTALLATIoN

Installation

www.stiebel-eltron.com

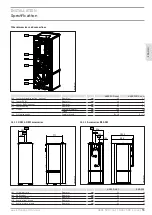

HSBC 300 cool | HSBC 300 L cool |

47

EN

GL

ISH

D

00000

80

42

9

1

2

1 Retainer

2 Insulated connection pipes

f

f

Install the connection pipes in sequence, starting on the left

or right depending on the positioning of the appliance.

f

f

Insert the connection pipes through the retainer from below.

f

f

Secure the connections to the appliance using the union nuts.

f

f

Connect the pipes of the pipe assembly to the domestic pipe-

work system.

10.3.3 Installing the DHW circulation line, if applicable

A DHW circulation line with external DHW circulation pump can

be fitted to the DHW circulation connection (see chapter "Specifi-

cation / Dimensions and connections").

f

f

Remove the sealing cap from the DHW circulation connection

(see chapter "Specification / Dimensions and connections").

f

f

Connect the DHW circulation line.

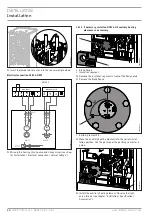

10.3.4 DHW connection and safety assembly

f

f

Flush the pipes thoroughly.

f

f

Install the DHW outlet line and the cold water inlet line (see

chapter "Specification / Dimensions and connections"). Con-

nect the hydraulic connections with flat gaskets.

f

f

Install a type-tested safety valve in the cold water inlet line.

Please note that, depending on the supply pressure, you may

also need a pressure reducing valve.

f

f

Size the drain pipe so that water can drain off unimpeded

when the safety valve is fully opened.

f

f

The safety valve drain aperture must remain open to

atmosphere.

f

f

Install the safety valve drain pipe with a constant fall to the

drain.

10.4 Filling the system

Heating circuit water quality

Carry out a fill water analysis before filling the system. This analy-

sis may, for example, be requested from the relevant water supply

utility.

To avoid damage as a result of scaling, it may be necessary to

soften or desalinate the fill water. The fill water limits specified

in chapter "Specification / Data table" must always be observed.

f

f

Recheck these limits 8-12 weeks after commissioning and

during the annual system service.

Note

With a conductivity >1000 μS/cm, desalination treatment

is recommended in order to avoid corrosion.

Note

If you treat the fill water with inhibitors or additives, the

same limits apply as for desalination.

Note

Suitable appliances for water softening, as well as for

filling and flushing heating systems, can be obtained via

trade suppliers.

!

Material losses

Never switch on the power before filling the system.

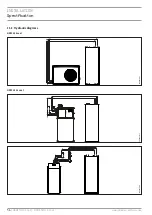

10.4.1 Filling the heating system

D

00000

80

42

5

f

f

Fill the heating system via the drain valve.

f

f

Vent the pipework.