5

Installation instructions

for the installer

Regulations and provisions

– General national regulations

– Regulations of the local water

authority

– Regulations of the local electricity

authority

– Rating plate

Installation location

– Install vertical as in Fig.

– In an area free of the risk of freezing

– Install in the vicinity of the water tap

Equipment installation

– Install the device

When installing the device, select securing

materials to suit the stability of the wall

Temperature adjustment Fig.

PSH 30 Si / PSH 50 Si

The temperature adjustment for the PSH 30

Si and PSH 50 Si may be altered by the user

directly at the temperature knob.

For PSH 80-150 Si see Fig. .

Water connection Fig.

Unvented (pressurized) for the supply of

several draw-off points.

A safety valve must be fitted with on

the cold water inlet of the unit, by a

skilled installer.

2. Installation instructions

for the qualified installer

Legend for Fig.

1

PSH wall-mounted water heater

3

Safety valve, 6 bar

4

Pressure Limiting valve

(recommended for pressures

over 5 bar)

5

Back-flow prevention device

6

Through-flow isolating valve

(throttle)

7

Cold water pipe

8

Drainage tap

9

Connection for isolating element

made of red brass or plastic, for

cold and hot water

10 Hot water pipe

11 Draw-off fittings

– Permissible operating

overpressure 6 bar.

– Install only type-tested safety

valves or safety groups.

Specific national regulations

are to be respected.

– Arrange the dimensions of the

drain to suit the fully-opened

safety valve. The drain aperture of

the safety valve must remain open

to the atmosphere.

– Adjust through-flow volume

max. 18 l/min at the through-flow

isolating valve (Fig.

-6).

– During the heating-up process,

water will visibly drip from the

safety valve.

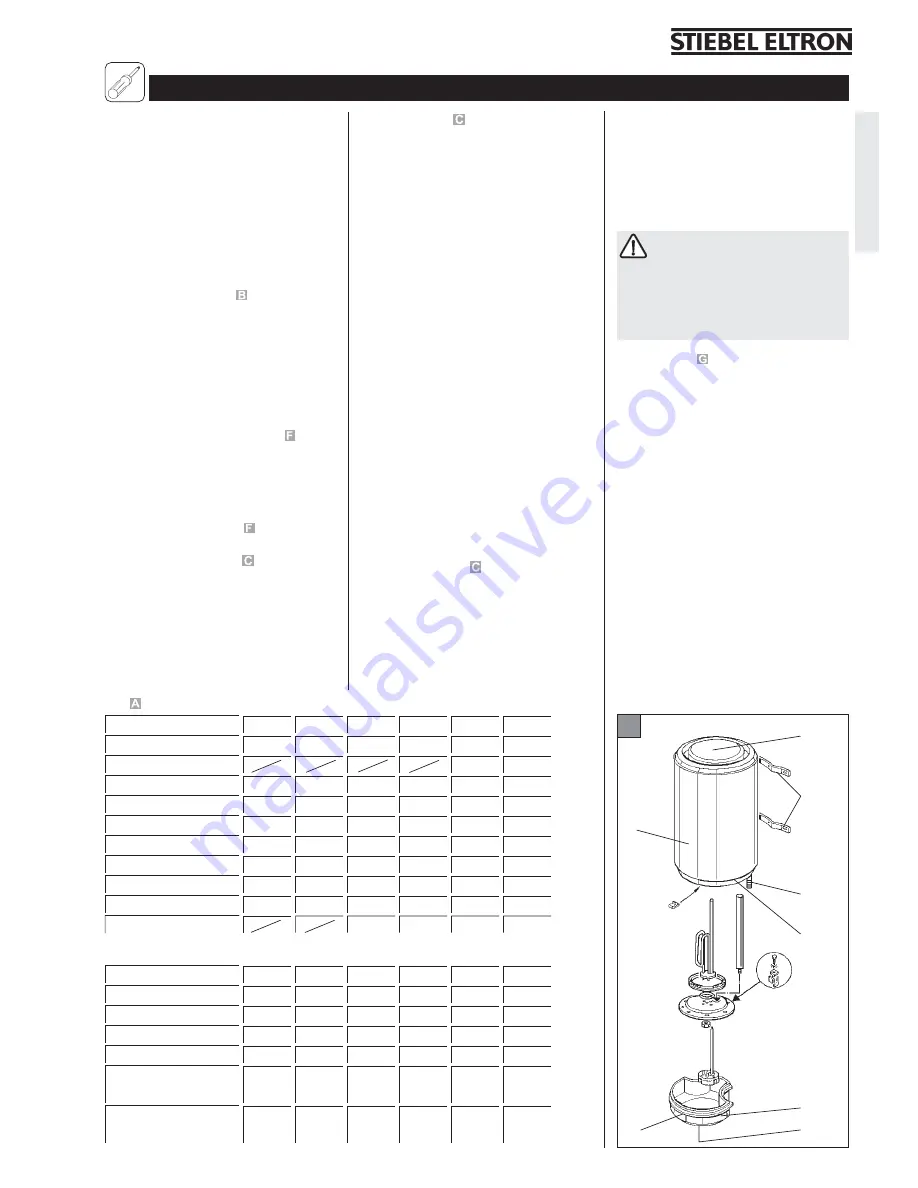

Parts Fig.

1 Plastic top cap

2 Wall brackets

(on PSH 30 - 100 Si, on top only)

3 Sheet steel housing, white

paint finish

4 Cold water connection nozzle (blue)

5 Hot water connection nozzle (red)

6 Plastic bottom cap

7 Electric housing with electrical

connection

8 Temperature knob (only PSH 30-50 Si)

9 Lamp

Steel tank enamelled with heating flange with

copper tubular heating element and

protection anode.

For test mark: see rating plate

Protection mode IP 25

G

– If water continues to drip from the

safety valve after the heating

system has been switched off, the

water pressure is too high (>6 bar),

or the safety valve has been

contaminated with dirt or is

defective.

Note with regard to copper pipes:

No connections made of copper

may be installed directly on the

device. We recommend that red

brass or plastic transition fittings be

used as connection isolators for the

pipe connections.

Type

PSH

30 Si

50 Si

80 Si

100 Si

120 Si

150 Si

Content

30

50

80

100

120

150

Weight, emty

kg

14

17

26

31

34

40

Power rating

W

2000

2000

2200

2200

2200

2200

Voltage

V

230

230

230

230

230

230

Permissible operating

pressure

bar

6

6

6

6

6

6

Standby current

consumption at

65 °C/24h

kW/h

0,73

0,99

0,97

1,21

1,3

1,46

Typ

PSH

30 Si

50 Si

80 Si

100 Si

120 Si

150 Si

A

mm

623

918

780

911

1046

1256

B

mm

498

798

C

mm

345

368

570

748

748

1048

D

mm

160

168

230

230

230

230

E

1/2"

1/2"

3/4"

3/4"

3/4"

3/4"

F

mm

100

100

230

230

230

230

G

mm

81

81

170

170

170

170

H

mm

338

338

505

505

505

505

J

mm

345

345

520

520

520

520

K

mm

440

440

440

440

Fig.

1

2

3

4, 5

6

7

8

9

English

Summary of Contents for PSH 150 Si

Page 18: ...18 2 1 2 3 4 5 6 1 2 3 4 PSH 80 150 Si 5 65 C 3...

Page 24: ...24 2 3 1 2 3 4 5 6 1 2 3 4 F PSH 80 150SI 5 65 C 1...

Page 28: ...28 Notizen...

Page 29: ...29 Notizen...