HTV`.HC

q+``HH.%ĪĪĪIJ

qqqĪZ`.<é<`VHCĪHB

ZH<ŝŌTVB.eBŝŗ

EN

GL

ISH

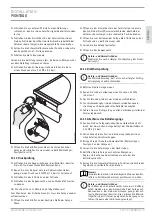

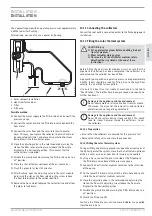

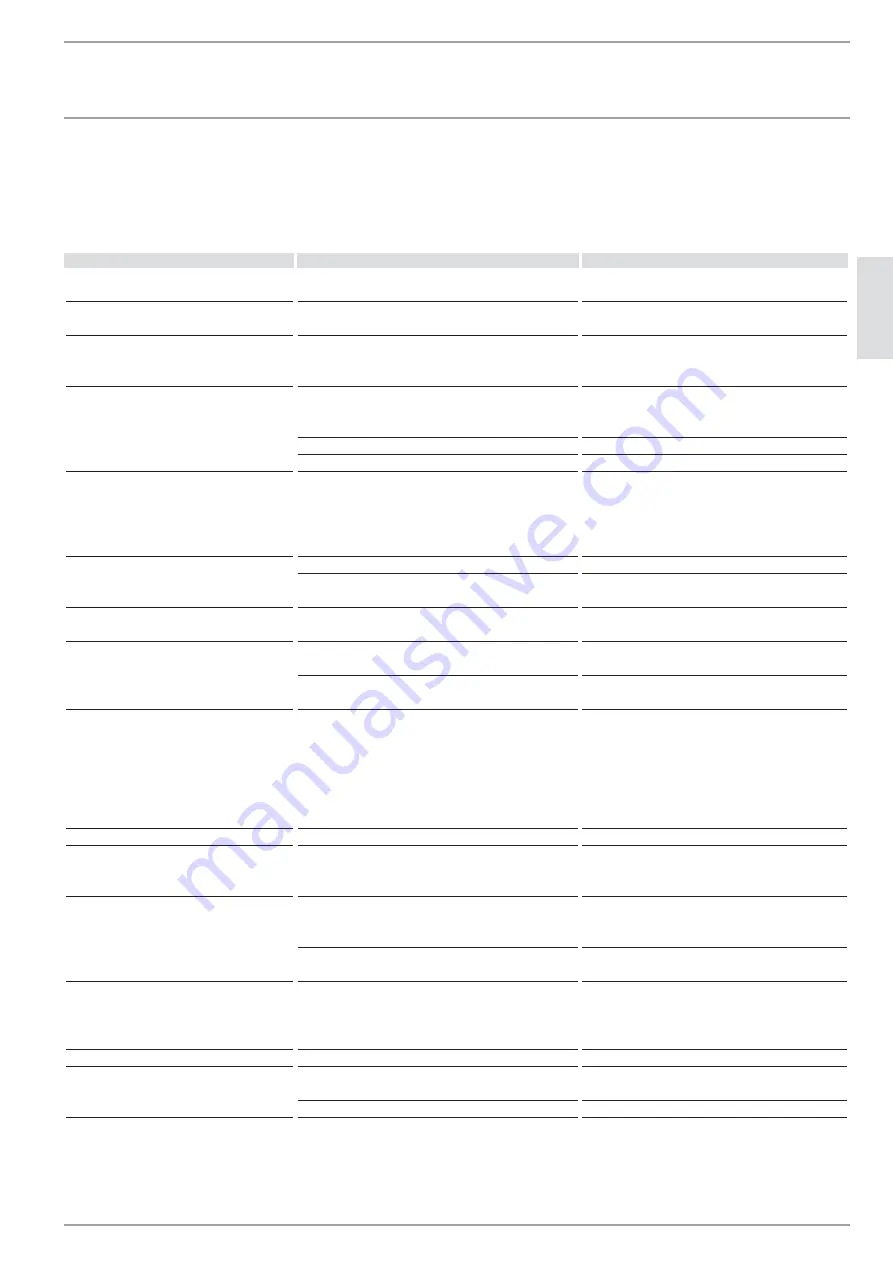

6. What to do if ... ?

The following contains descriptions of what measures to take in

order to remedy faults. If you are still unable to fix the problem

using this information, please consult your heating contractor.

%|şùŒ

|şń¼

V¼ă¼®ź

Fault/error message at the controller.

There is a fault in the system; the sensor is faulty or

incorrectly connected.

Please refer to the controller operating and

installation instructions.

Pressure fluctuations in the system.

If the problem occurs immediately after commissioning,

there is air in the solar circuit.

Please consult a qualified contractor.

The collectors are misted up.

Moisture has entered the collector during storage.

The internal mist will evaporate after a few weeks

in operation. The moisture will progressively escape

through the integral ventilation slots.

The pump does not run although the collector

is warmer than the cylinder (no noise from the

motor, no noticeable vibration).

The maximum cylinder or collector temperature is

exceeded. The control indicator or display on the

controller is activated.

The controller has shut down correctly and restarts

again automatically when the actual temperature

drops below their selected maximum temperature.

The power supply is interrupted.

Check fuses/MCBs.

Other cause.

Please consult a qualified contractor.

The pump is running, but no flow rate is

discernible at the flow meter with balancing

valve. The flow and return temperatures are

identical or the cylinder temperature does not

rise or rises only slowly.

Please consult a qualified contractor.

The pump is running, but no flow rate

is discernible at the flow meter with

balancing valve.

The shut-off valve is closed.

Open the shut-off valve.

Other cause.

Please consult a qualified contractor.

The pump appears to open late and switch

itself off early.

Please consult a qualified contractor.

The pump starts and switches itself off again

shortly afterwards. This repeats a few times

until the system runs correctly. The same

happens in the evening.

There is still too little insolation to heat up the

entire pipework.

Check for faults again when there is strong insolation.

Other cause.

Please consult a qualified contractor.

The pressure gauge indicates a drop

in pressure.

A pressure drop shortly after the system is filled is

quite normal, as air is still escaping from the system. A

pressure drop later on can be caused by an air lock that

has shifted. In addition during normal operation, the

pressure fluctuates by 0.02-0.03 bar depending on the

system temperature. If the pressure drops continuously,

the system is leaking somewhere.

Please consult a qualified contractor.

The pump runs noisily.

Please consult a qualified contractor.

The system runs noisily. This is normal in the

first few days after filling the system. If this

occurs later:

Please consult a qualified contractor.

The cylinder cools down over night. After

the pump has stopped, the flow and return

operate at different temperatures. At night the

collector temperature is higher than the out-

side temperature.

The gravity brake does not close.

Check the position of the adjusting screw on the

gravity brake.

Other cause.

Please consult a qualified contractor.

Reheating does not work. The boiler runs for

a short while, stops and starts again. This

repeats frequently, until the cylinder has

reached its set temperature.

Please consult a qualified contractor.

The cylinder cools down excessively.

Please consult a qualified contractor.

The pump does not switch off.

The control unit is faulty.

The variable speed pump does not stop immediately

but only after it reaches its lowest speed.

Other cause.

Please consult a qualified contractor.