qqqĪZ`.<é<`VHCĪHB

ZH<ŝŌTVB.eBŝÑ

EN

GL

ISH

.CZ`<<`.HC

.CZ`<<`.HC

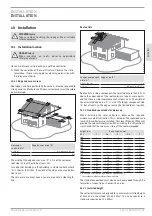

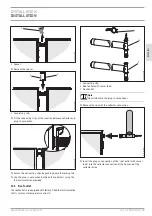

9. Installation

Only qualified contractors should carry out installation,

commissioning, maintenance and repair.

Observe the accident prevention instructions.

Note

For hydraulic reasons, never link up more than five

collectors in series. Where several rows of collectors are

fitted, they must be connected in parallel

.

Note

The type-testing is limited to single hydraulic assemblies

of no more than 30 individual collectors. An individual

inspection is required for larger systems.

Note

Commercial systems, the open content of which exceeds

10 litres and is not more than 50 litres, require notification

to the relevant local authority [in Germany - check local

regulations].

Damage to the appliance and environment

When filling the solar thermal system with frost and

corrosion protection, use only the heat transfer medium

which is mentioned in the table "Specification".

9.1 Preparations

Provide all pipe runs to the building interior on site.

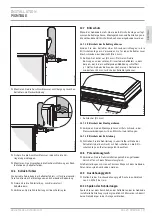

9.2 Pipework

installation

Use copper, stainless steel or corrugated stainless steel hoses when

installing the flow and return lines. With a system comprising up

to four collectors, we recommend a pipe diameter of Ø 18 x 1.0.

Ventilation tiles are recommended as roof outlets for tiled or

slate-covered roofs with more severe inclination.

For flat roofs and corrugated roofs with lesser pitches, routing the

pipes through an external wall is recommended.

Avoid sawing off pipes to prevent swarf entering the system. Use

a pipe cutter for swarf-free cutting.

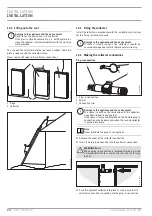

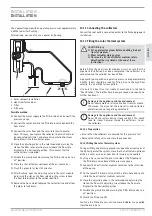

9.2.1 Soldered

lines

Soldered lines must be brazed. Use solder to DIN EN 1044: CP105

and CP203. Use this solder without flux. Only solder gunmetal

and brass fittings with flux F-SH-1 to EN 1045. Other flux has a

detrimental effect on corrosion resistance.

9.2.2 Alternative

lines

Seal lines made with locking ring fittings, press fittings and

corrugated hoses by suitable means. Seals must be resistant to

glycol and temperatures up to 180 °C.

Damage to the appliance and environment

Apply the thermal insulation only following a successful

leak test.

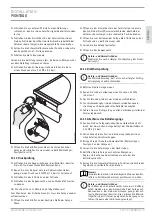

9.3

Air vent valve

Install a lockable manual air vent valve at a high point of the system

or route a ventilation line to a manual air vent valve. Automatic

quick-acting air vent valves installed close to the collector must be

able to be isolated from the system with a shut-off valve.

9.4 Safety

valve

Damage to the appliance and environment

There must not be any shut-off fittings between the

collectors and the safety valve.

The safety valve must discharge into a container that can hold the

entire content of the system. In case of smaller systems, the empty

heat transfer medium can is adequate.

9.5 Drain

facility

f

Install a drain valve at the lowest point of the solar thermal

system.