qqqĪZ`.<é<`VHCĪHB

ZH<ŝŌTVB.eBŗĜ

EN

GL

ISH

.CZ`<<`.HC

.CZ`<<`.HC

Use a powerful pump with an operating pressure of approximately

0.4 MPa (4 bar) for flushing.

Alternatively, you can also use a power drill pump.

2

6

_0

5_0

1

_0

5

1

5

2

1

3

4

4

4

4

4

4

4

4

4

4

4

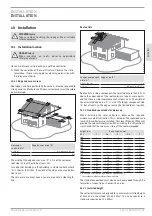

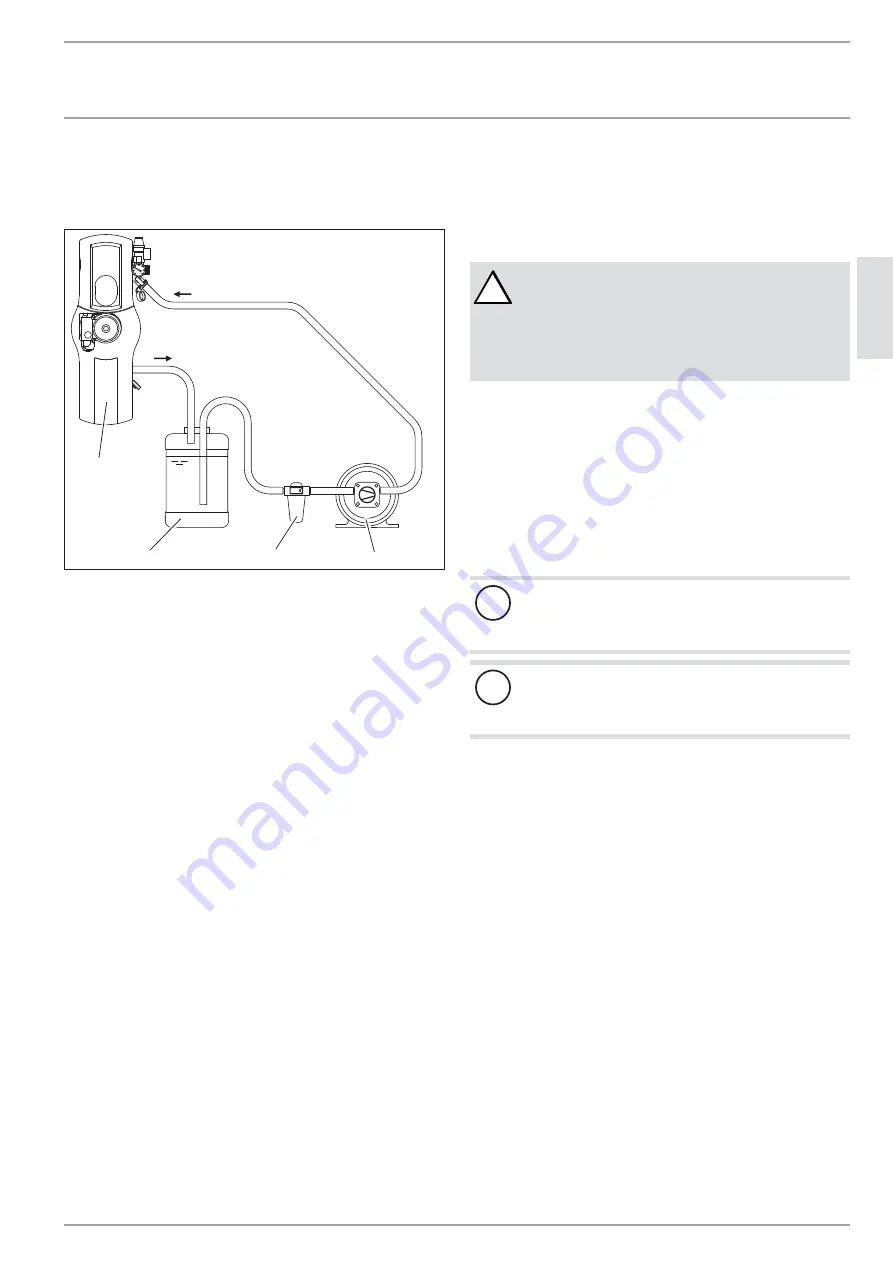

1 Solar compact installation

2 Heat transfer medium

3 Filter

4 Fill pump

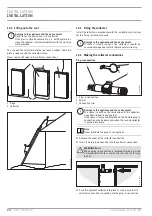

Possible method:

f

Connect the water supply to the fill & drain valve beneath the

pressure gauge

f

Connect the water drain to the fill & drain valve beneath the

flow meter.

f

Connect the solar flow and the solar return with a water

hose. This way, you replace the collector line which will not

be connected until later, and prevents contamination from

being drawn into the collector pipes.

f

Close the adjusting valve in the solar module by turning the

slot on the flow rate adjusting screw (above the flow rate

display) to the horizontal position. This ensures that the

entire system is supplied.

f

Disable the gravity brake by turning the fill & drain valve to a

45° position.

f

Close the shut-off valves upstream of the air vent valves.

f

Flush the pipes for at least 15 minutes.

f

After flushing, open the adjusting valve in the solar module

by turning the slot on the flow rate adjusting screw (above

the flow rate display) to the vertical position.

f

Remove the hose which replaced the collector line and allow

the pipes to fully drain.

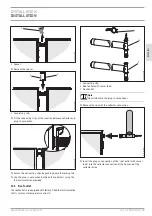

10.11 Connecting the collectors

Connect the roof outlets connected earlier to the flushed pipework

installation.

10.12 Filling the solar thermal system

!

CAUTION Injury

f

Put on protective gloves before handling the heat

transfer medium.

f

Wear suitable safety goggles.

f

Observe the EC's heat transfer medium safety

datasheet that is printed at the end of these

instructions.

Before filling the heat transfer medium circuit, ensure that the

pipework installation has been completed, the collectors are

connected and the cylinder has been filled.

A powerful pump with an operating pressure of approximately

0.4 MPa (4 bar) should be used for filling. Due to the high flow

velocity, the air will be fully expelled.

Use only the heat transfer medium mentioned in the table

"Specification". The bottles have been premixed and require no

further treatment.

Damage to the appliance and the environment

Never admix water or alternative heat transfer media.

Otherwise, the essential characteristics and corrosion

protection can no longer be guaranteed.

Damage to the appliance and the environment

Never fill the system during strong sunlight. This could

lead to steam hammer inside the collectors. Cover

the collectors.

10.12.1 Preparation

» Ensure that the collectors are covered for the pressure test.

» Remove the safety valve and close the connection.

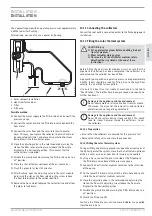

10.12.2 Filling the solar thermal system

During all filling and draining procedures, open the air vent valve at

the highest point of the system. Close the shut-off valves upstream

of the air vents as soon as heat transfer medium is expelled.

f

Using a hose, connect the pressure side of the fill pump to

the fill & drain valve beneath the pressure gauge.

f

Connect the heat transfer medium container to the inlet side

of the pump.

f

On the lower fill & drain valve, attach a drain hose and route

it into the heat transfer medium container.

f

Close the adjusting valve in the solar module by turning the

slot on the flow rate adjusting screw (above the flow rate

display) to the horizontal position.

f

Disable the gravity brake by turning the fill & drain valve to a

45° position.

f

Switch the fill pump ON.

Continue the filling process until no more bubbles are expelled

from the drain hose.