ŗŝ

ZH<ŝŌTVB.eB

qqqĪZ`.<é<`VHCĪHB

.CZ`<<`.HC

.CZ`<<`.HC

f

Close the drain valve and fill up to a pressure of

approximately 0.35 MPa (3.5 bar).

2

6

_0

5_0

1

_0

6

4

8

f

Open the air vent valves at the highest point of the system

and close them again as soon as heat transfer medium is

expelled.

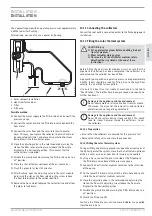

10.13 Pressure test

f

Close the shut-off valves upstream of the air vent valves to

eliminate a loss of pressure.

f

Using a hydraulic lifting pump, for example, pressurise the

system to 0.78 MPa (7.8 bar) in the system.

f

Close the fill & drain valve on the filling side.

f

Close the cap valve in order to be able to measure the

pressure drop.

The pressure must not drop for 15 minutes.

The system must be drained again to assemble the safety valve.

f

Open the air vent valve at the highest point of the system.

f

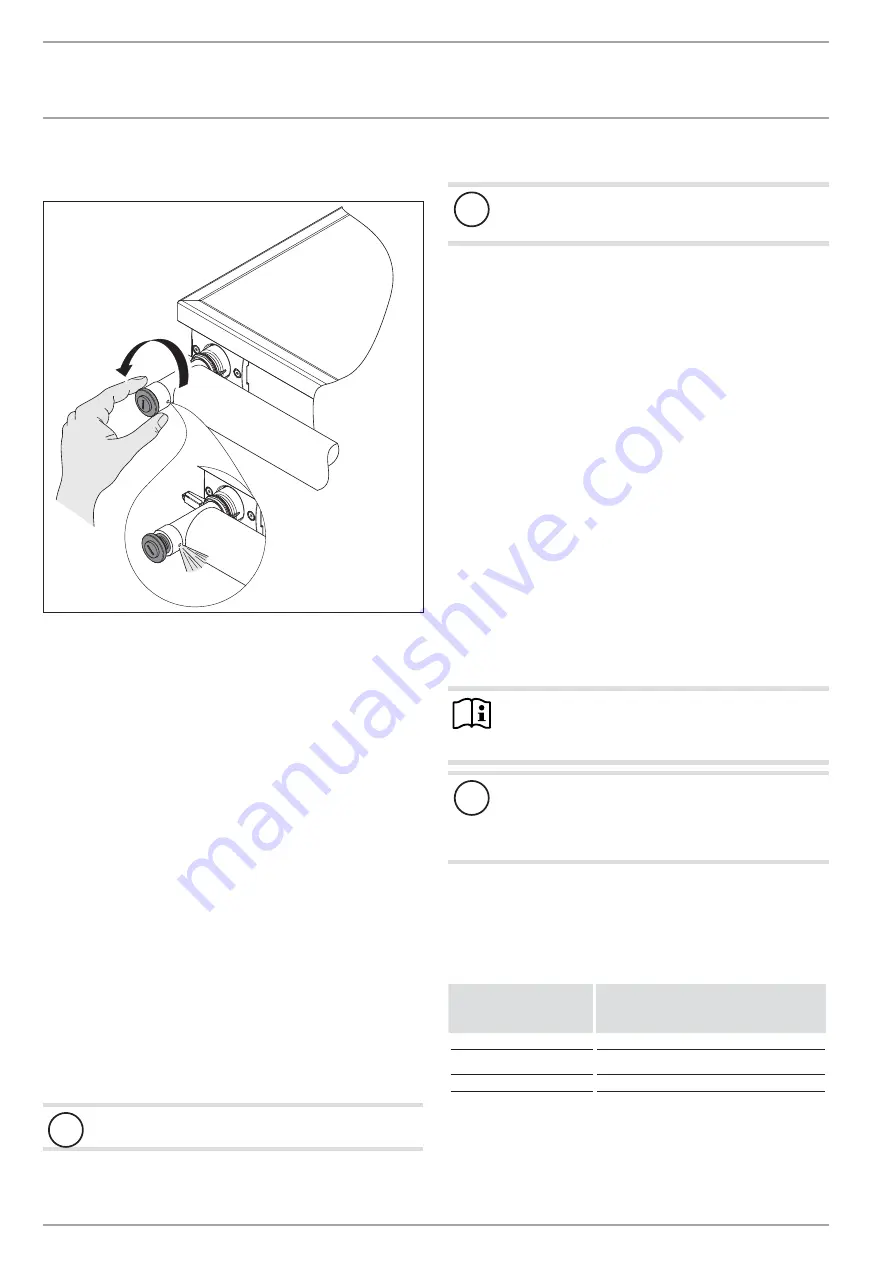

Open the adjusting valve in the solar module by turning the

slot on the flow rate adjusting screw (above the flow rate

display) to the vertical position.

f

To drain the system, open the fill & drain valves on the fill

and drain sides.

f

Allow the system to fully drain.

f

Open the cap valve.

Damage to the appliance and the environment

Following a pressure test, fit the safety valve.

10.14 Checking the system for leaks

Damage to the appliance and the environment

The thermal insulation may only be applied following a

successful leak test.

f

Refill the system.

f

Using the fill pump, build a pressure of 0.5 MPa (5 bar).

f

The test pressure must not drop for a period of two hours.

f

Pressure fluctuations are possible due to changing insolation

even when the collectors are covered.

f

Carry out a visual inspection of all joints on the solar thermal

system.

10.15 Completing the filling procedure

f

Reduce the system pressure to the required filling pressure.

The minimum filling pressure of a cold system is 0.35 MPa

(3.5 bar).

f

Close both fill & drain valves with the caps supplied.

f

Attach the heat transfer medium safety datasheet to the

system.

f

Allow the solar thermal system to rest overnight.

f

Before the onset of strong sunlight, vent the system once

more the following morning using the air vent valve.

f

Enable the gravity brake by turning the fill & drain valve to a

vertical position.

Note

During normal operation, the shut-off valves upstream

of the air vent valves in close proximity to the collector

must always be kept closed.

Damage to the appliance and the environment

The safety valve drain must terminate in a container that

can hold the entire system contents. In case of smaller

systems, the empty heat transfer medium can is adequate.

Dispose of spent process medium by permissible means.

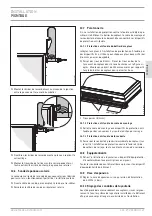

10.16 Thermal insulation

Ensure that the system undergoes a pressure test and a leak test

before applying thermal insulation.

Insulate all pipes. The insulation material is to be provided on site.

.ĉŒ¼ļĉ|ùĤêĤ¼®ê|ă¼Œ¼ļ

ăă

`äê÷ĉ¼ńńĒÏêĉńşù|ŒêĒĉĦļ¼ù|ŒêŶ¼ŒĒ|

Œä¼ļă|ùĒĉ®şŒêŶêŒźĒÏƃĪƃŗÑqŎĦă:ħ

|ŒÔƃ³

C)

to 22

20

22 - 35

30

35 - 100

same as internal pipe diameter

For insulation material with a different thermal conductivity,

re-calculate the thickness of the insulation layer.

Use temperature and UV-resistant insulation material to provide

thermal insulation for the external pipes: Mineral wool which

is backed by aluminium mesh foil, a flexible EPDM hose or a

closed-pore EPDM hose.