page

56

Release 00 - 03/2018

Engine RS100 - RSC100

Service manual

15. ENGINE BLOCK - Overhauling internal parts

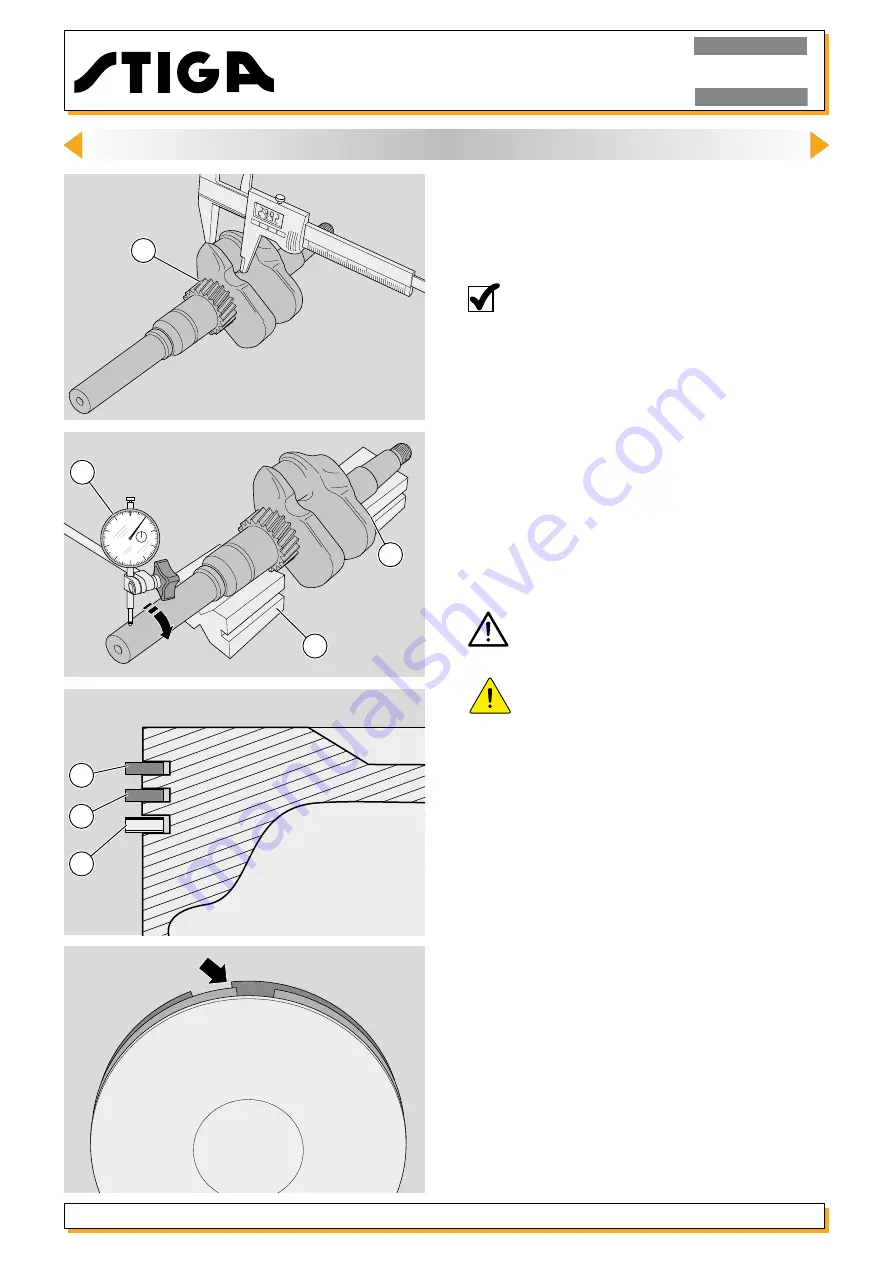

16 - On the engine shaft (

26

), removed beforehand,

use a digital gauge to check the diameter of the

connecting rod pin.

The value must not be less than 23.92 mm or the

engine shaft will have to be replaced.

NOTE - In the case of seizing, the manifolds

can be polished with fine emery cloth, only

removing foreign matter and checking that

the final size remains within the aforementio-

ned limit.

17 - To check the alignment between the mani-

folds and the protruding part of the shaft, place

the engine shaft on two prismatic guides (

33

) and,

with the help of a comparator (

34

) placed at the

end, check the displacement by rotating the shaft.

The shaft must be replaced if the displacement

exceeds 0.10 mm.

IMPORTANT: A bent shaft must never be re-

paired!

WARNING - DANGER: A bent shaft causes ab-

normal vibrations and could be dangerous

when the machine is used!

18 - To refit the rings to the piston, first fit the three

oil scraper rings (

35

), then the ring with a round

edge (

36) and finally the ring with a sharp edge

(

37

), being careful over the markings (which must

face the piston head) and in arranging the gaps to

ensure that they are not aligned with each other;

37

36

35

10

20

30

40

50

60

70

80

90

26

34

33

33

D

<< BACK >>

INDEX