16.2

During work

NOTICE

Do not make the mixture leaner to achieve an

apparent increase in power – this could damage

the engine – see "Adjusting the Carburetor".

NOTICE

Open the throttle only when the chain brake is

off. Running the engine at high revs with the

chain brake engaged (chain locked) will quickly

damage the shortblock and chain drive (clutch,

chain brake).

16.2.1

Check chain tension frequently

A new saw chain must be retensioned more fre‐

quently than one that has been in use already for

an extended period.

16.2.2

Chain cold

Tension is correct when the chain fits snugly

against the underside of the bar but can still be

pulled along the bar by hand. Retension if neces‐

sary – see "Tensioning the Saw Chain".

16.2.3

Chain at operating temperature

The chain stretches and begins to sag. The drive

links must not come out of the bar groove on the

underside of the bar – the chain may otherwise

jump off the bar. Retension the chain – see "Ten‐

sioning the Saw Chain".

NOTICE

The chain contracts as it cools down. If it is not

slackened off, it can damage the crankshaft and

bearings.

16.2.4

After a long period of full-throttle oper‐

ation

After a long period of full-throttle operation, allow

engine to run for a while at idle speed so that the

heat in the engine can be dissipated by flow of

cooling air. This protects engine-mounted com‐

ponents (ignition, carburetor) from thermal over‐

load.

16.3

After finishing work

► Slacken off the chain if you have retensioned it

at operating temperature during work.

NOTICE

Always slacken off the chain again after finishing

work. The chain contracts as it cools down. If it is

not slackened off, it can damage the crankshaft

and bearings.

16.3.1

Short-term storage

Wait for engine to cool down. Keep the machine

with a full tank of fuel in a dry place, well away

from sources of ignition, until you need it again.

16.3.2

Long-term storage

See "Storing the machine"

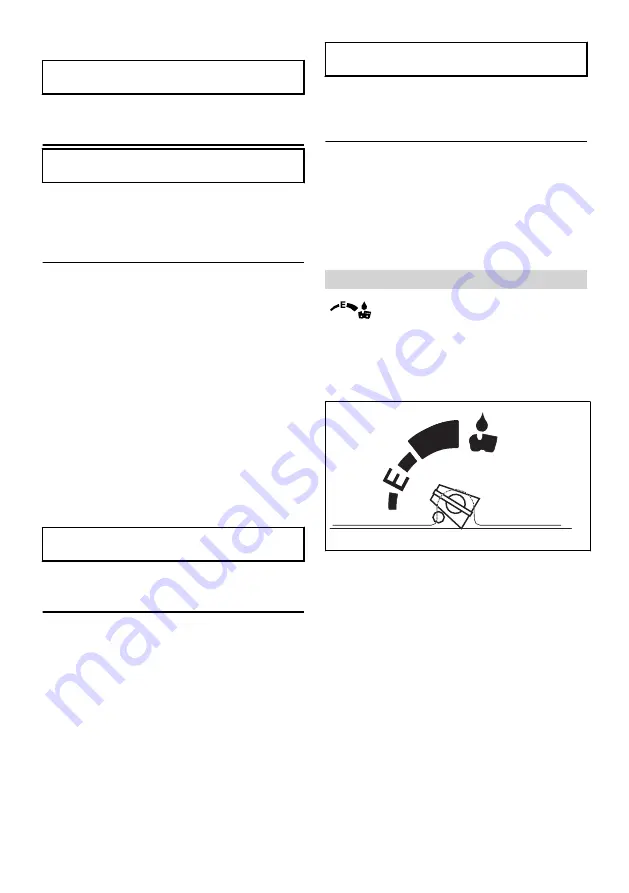

17 Oil Quantity Control

Varying cutting lengths, types of wood and work

techniques require varying amounts of oil.

17.1

Standard setting

1

2

1166BA009 AM

The oil flow can be adjusted as needed using the

adjusting screw (1) (on the bottom of the

machine).

Ematic position (E), medium oil flow –

► Turn adjusting screw to "E" (Ematic position)

To increase oil flow –

► Turn the adjusting screw clockwise – adjusting

screw is limited by end stop (2)

To reduce oil flow –

► turn the adjusting screw counterclockwise

17 Oil Quantity Control

English

0458-562-8721-B

67

Summary of Contents for MS 382

Page 1: ...MS 382 Manual de instrucciones Instruction Manual 2 43 43 81 2 43 43 81...

Page 82: ...English 32 EC Declaration of Conformity 82 0458 562 8721 B...

Page 83: ...32 EC Declaration of Conformity English 0458 562 8721 B 83...

Page 84: ...www stihl com 04585628721B 04585628721B 0458 562 8721 B 0458 562 8721 B...