4.10

Cleaning, Maintenance and

Repair

WARNING

■ The gear housing can get hot during opera‐

tion. There is a risk of burn injuries.

► Do not touch a hot gear housing.

■ Harsh detergents, cleaning with a water jet or

sharp objects can damage the KombiTool. If

the KombiTool is not cleaned correctly, com‐

ponents may no longer function properly or

safety devices may be rendered inoperative.

They may cause serious injury to persons.

► Clean the KombiTool as described in this

instruction manual.

■ If the KombiTool is not serviced or repaired

correctly, components may no longer function

properly or safety devices may be rendered

inoperative. This may result in serous or fatal

injury to people.

► Do not attempt to repair the KombiTool

yourself.

► If the KombiTool needs to be repaired: Con‐

tact a STIHL servicing dealer for assis‐

tance.

► Maintain the KombiTool as described in this

instruction manual.

■ The user can be cut by the sharp cutting

edges while cleaning or maintaining the

blades. This may result in injury to the user.

► Wear work gloves made from resist‐

ant material.

5

Preparing KombiTool for

Operation

5.1

Preparing KombiTool for Oper‐

ation

Perform the following steps before starting work:

► Make sure the following components are in a

safe condition:

–

–

KombiMotor, as described in the instruction

manual.

► Clean the KombiTool, 12.1.

► Connect drive tube to the gearbox, 6.1.

► Mount the KombiTool on the KombiMotor,

► If you are using a KombiMotor with a loop han‐

dle: Mount a barrier bar as described in the

KombiMotor’s instruction manual.

► If you cannot carry out the above steps: Do

not use the KombiTool and contact your

STIHL servicing dealer for assistance.

6

Assembling the KombiTool

6.1

Connecting Drive Tube to Gear

Housing

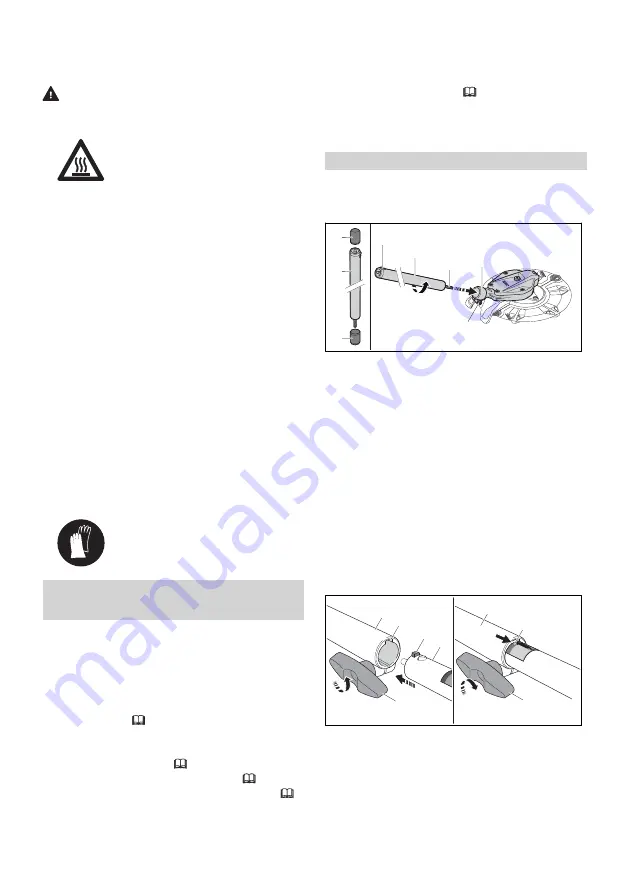

6

2

4

5

3

1

2

1

0000-GXX-8735-A1

► Remove protective caps (1) from both ends of

the drive tube (2).

► Loosen the screw (6).

► Push the drive tube (2) into the gear housing

(5) and rotate it until the gear shaft (4)

engages.

► Tighten the screw (6) moderately.

► Align the drive tube (2) so that the lug (3)

faces up.

► Tighten down the screw (6) firmly.

The drive tube need not be removed again.

6.2

Mounting and Removing the

KombiTool

6.2.1

Mounting the KombiTool

2

4

1

5

3

6

1

2

0000-GXX-4689-A0

► Loosen the wing screw (1).

► Line up the lug (4) and the slot (3).

► Push the drive tube (5) into the coupling

sleeve (2) as far as stop.

The red line (6) is flush with the coupling

sleeve (2).

► Tighten down the wing screw (1) firmly.

English

5 Preparing KombiTool for Operation

6

0458-811-0121-C