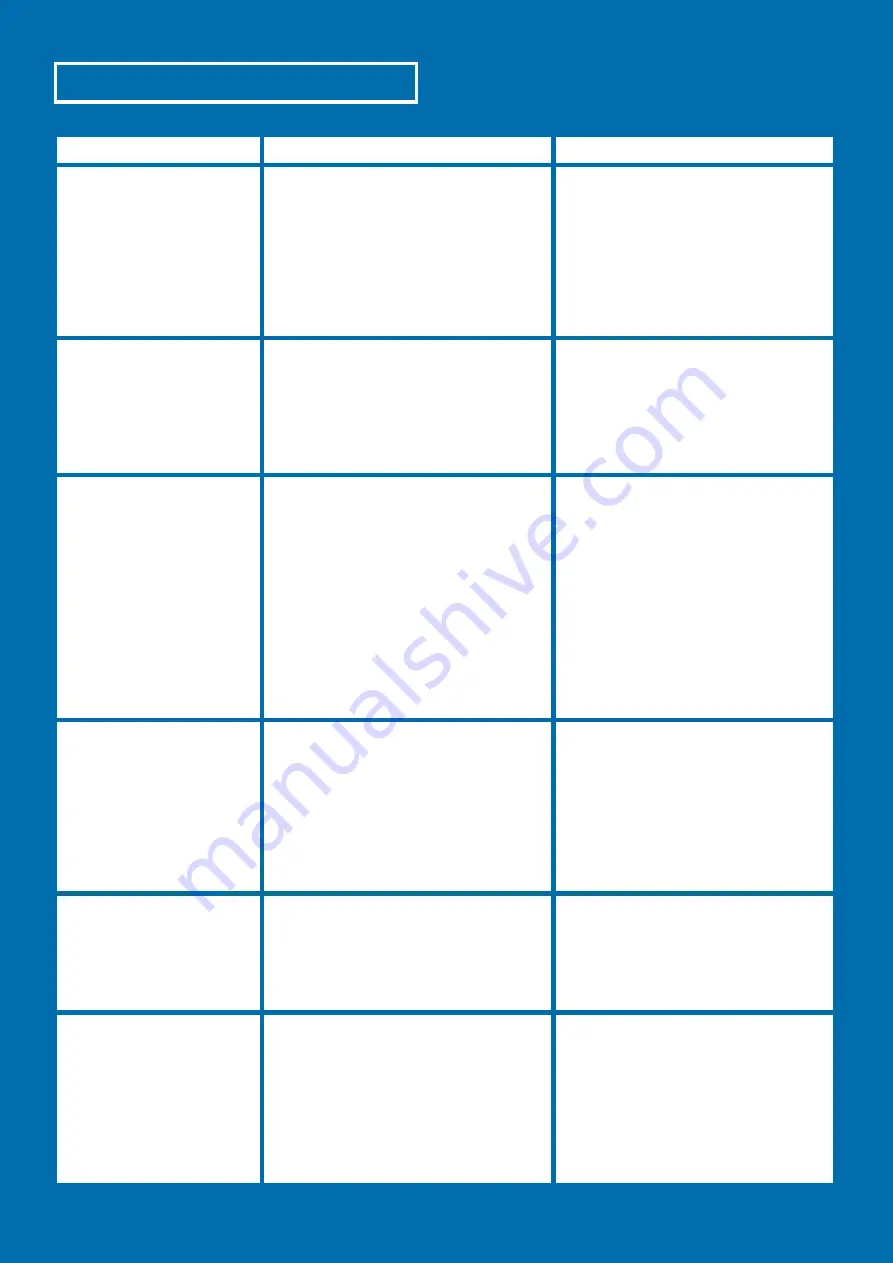

10

WHAT IS THE PROBLEM?

WHY IS IT HAPPENING?

HOW TO FIX IT?

Alcohol distillate flows

irregularly.

•

Wash is surge boiling caused by hot spot

on base of integrated boiler.

•

Spirit outlet pipe is higher than outlet

creating an airlock or is submerged in

distillate causing alternating pressure

and vacuum.

•

Add ceramic boil enhancers. In extreme

cases try adding 1–2 stainless steel pot

scrubbers.

•

Make sure the outlet pipe allows the

water to flow downwards from the

condenser outlet.

Trim outlet pipe so that it cannot

be below the level of the collected

distillate.

No alcohol is coming out.

•

This may be due to the cooling water

being too cold or its flow rate too high.

•

This may be due to an incorrect position

of the tubes.

•

There may be a blockage at the end of

your alcohol outlet tubing.

•

Ensure the cooling water outlet

temperature is between 50-65°C

(122-149°F) during distillation.

•

Check the tubes are in the correct

position (refer to Step 2 and 3).

•

Remove the plug at the end of your

alcohol outlet tubing.

The spirit is coming out

cloudy/milky.

•

Wash is foaming while boiling and

carrying fermentation residues up the

column.

•

Unfermented sugar in your wash can

cause foaming which eventually made its

way up into the condenser causing the

temperature fluctuations and producing

undesirable, cloudy spirit.

•

Always ensure your wash is completely

fermented (refer to Step 1 on

fermentation).

•

Only fill wash to MAX line on inside

of boiler if using the 30 L (8 US Gal)

boiler. The 4.9 L (1.3 US Gal) boiler has

more tolerance and can be filled up to

8 L (2.1 US Gal).

•

Add 3 capfuls of Still Spirits Distilling

Conditioner to the wash. This stops

excessive foaming in the boiler.

•

Add ceramic boil enhancers in your

boiler. Re distil the bad spirit.

Spirit has a strong

unpleasant smell,

described as ‘paint

thinner’, ‘hospital’, ‘burnt’,

‘nail polish’.

•

Distillate coming out of the Turbo 500

is at approx 93% ABV and has a strong

ethanol smell.

•

The first 50 ml (2 US fl oz) of distillate

has a stronger smell (nail polish type),

because it contains most acetaldehydes

and esters. This should be discarded.

•

The rest of the distillate smells like

ethanol.

•

Water down and filter your distillate

with activated carbon. It will trap most

unwanted flavours, leaving you a clean

spirit (refer to activated carbon in the

glossary).

Spirit has a blue tint.

•

This is caused by unbalanced or excessive

nutrients added in the fermentation

vessel. Nutrients are essential for

the yeast to ferment sugars; they are

precisely dosed and included in every Still

Spirits Turbo Yeast sachet.

•

Use only 1 sachet of Still Spirits Turbo

Yeast per 25 L (6.6 US Gal) of wash.

•

Follow recommended recipes for each

type of Turbo Yeast.

The yield is low.

•

The wash has not fermented out

properly so the amount of alcohol

available is reduced. This could be due

to several factors:

•

The sugars were not fully dissolved.

•

The fermentation temperature is too low

or too high.

•

Steam and vapour pressure is leaking

from lid seal.

•

Check the fermentation is finished

(refer to FAQs about fermentation).

•

Check lid gasket is sitting evenly inside

lid before clipping onto the base.

TROUBLE SHOOTING GUIDE