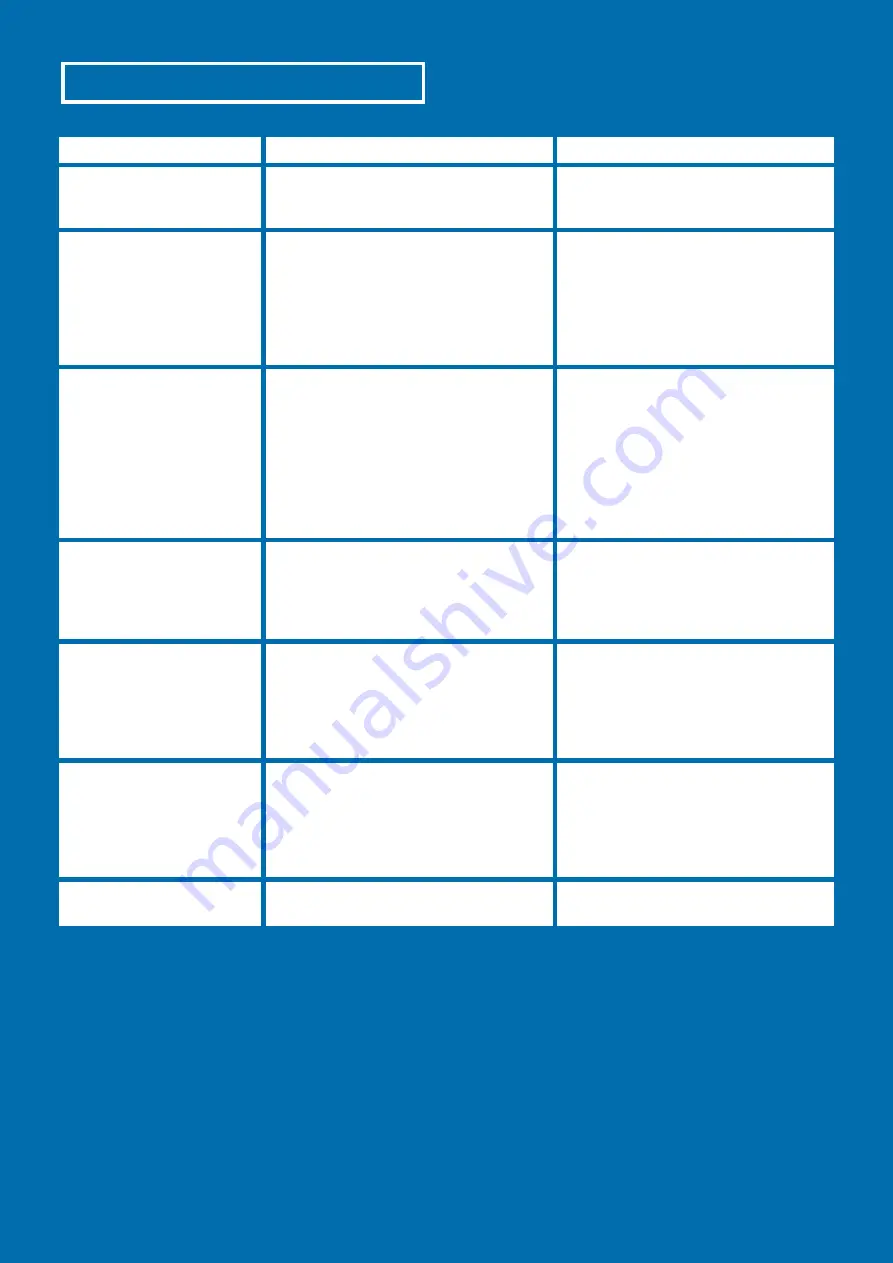

11

WHAT IS THE PROBLEM?

WHY IS IT HAPPENING?

HOW TO FIX IT?

Spirit purity is low.

•

The column temperature has been too

hot. This can cause the spirit to flow at a

higher but less concentrated rate.

•

Check that the water out temperature is

no more than 65°C (149°F).

The boiler has stopped

heating.

•

This is likely due to an electrical fault

or the boiler overheating. The boiler

has a thermostat cut out switch which

will automatically turn off the unit if it

goes above 125°C (257°F). It also has a

protective fuse in case the thermostat

cut out doesn’t operate.

•

Press the reset stick under the base of

the boiler to reset the thermostat.

If the boiler still doesn’t heat up, an

electrician will need to check it out.

My spirit is turning cloudy

when I add a spirit

flavouring or when I add

water.

•

This may be due to a poor carbon

filtration, or to the mineral salts

contained in some carbons.

•

This may be due to flavouring compounds

or caramel colour that is unstable in

alcohol/water.

•

Always carbon filter your spirit with

the Still Spirits EZ Filter cartridge with

our universal carbon, (remember to

prewash your carbon).

If the spirit is hazy, add more alcohol in

your drink (50% ABV). If the spirit has

suspended particles, leave it to sit for a

few days and decant it off into another

bottle once sediment has settled.

Fluctuating temperatures

while distilling.

•

This may be caused by inconsistent water

flow/pressure or others using water

outlets/taps in the house.

•

It may be caused by frothing of the wash

up the column.

•

Adjust water flow by opening/closing

the water flow controller valve. Use the

Still Spirits Water Flow Regulator if you

have one.

Alcohol is leaking from the

top of the condenser.

•

This may be due to saddles blocking

the alcohol steam path and building

some pressure.

•

There may be a blockage at the end of

your alcohol outlet tubing.

•

Turn off your boiler, let it cool down.

Remove all saddles from the column and

place them back in (copper saddles first,

followed by stainless steel saddles).

•

Remove plug at the end of your alcohol

outlet tubing.

Alcohol is leaking from

behind black plastic

brackets.

•

Potential sealing issue, or pressure

blockage in column.

•

Turn off your boiler, let it cool down.

Remove all saddles from the column

and place them back in (copper saddles

first, followed by ceramic saddles). If

this doesn’t solve the problem, contact

your retailer.

The condenser leaks when

I clean it

.

•

The still is vented at the top, so it will

leak water when you are cleaning it.

•

Normal, no need to fix.

TROUBLE SHOOTING GUIDE