12

WHAT IS THE BLACK STUFF I ADD IN MY WASH?

It’s activated carbon, designed to absorb unwanted

flavours produced during fermentation (see question

:

Is it normal that my wash smells funny?). It comes in

different formats: powder, granules or liquid.

The carbon will turn the liquid black and won’t

dissolve. It will not harm the fermentation process.

The carbon is removed when the wash is cleared.

I’VE ADDED MY YEAST IN A WASH AT 40°C (104°F), WILL

IT STILL WORK?

Yes, yeast can be safely added in a wash between

20-40°C (68-104°F) maximum. Above 40°C (104°F), yeast

will die very promptly if the wash is not cooled down

quickly. This can be done by resting the fermenter in a

basin or bath of cold water.

HOW LONG IS THE FERMENTATION?

A wash usually takes between 4 and 10 days to ferment

depending on the yeast used and temperature.

IS IT NORMAL THAT MY WASH SMELLS FUNNY?

During fermentation, yeasts produce alcohol, CO2, as

well as hundreds of by-products, which have different

smells, some pleasant (like pear, apple, banana), others

less pleasant (like rotten egg). This will not taint your

distilled spirit and will disappear after distillation. Carbon

filtration will further remove those unwanted smells.

HOW DO I KNOW WHEN THE FERMENTATION

IS FINISHED?

A few ways:

1. Measure your SG with a hydrometer: start of

fermentation reads around 1.100 and end of

fermentation reads about 0.990. When your SG has

read 0.990 for two consecutive days, fermentation

is complete.

2. Look for fizziness, bubbles rising to the surface: while

it’s fermenting there are lots of bubbles coming to the

surface and at the end of fermentation there are

almost none.

3. Look for the haze in the wash: at the beginning

of fermentation, the wash will be very murky and

hazy, towards the end, it will start to become more

‘transparent’.

WHAT’S IN THE CLEARING AGENT AND HOW DOES

IT WORK?

The Still Spirits Turbo Clear is made of silica (Part A)

which charges floating particles and chitosan (Part

B) attracts all particles (with its opposite charges) to

eventually make them all settle on the bottom of

the fermenter.

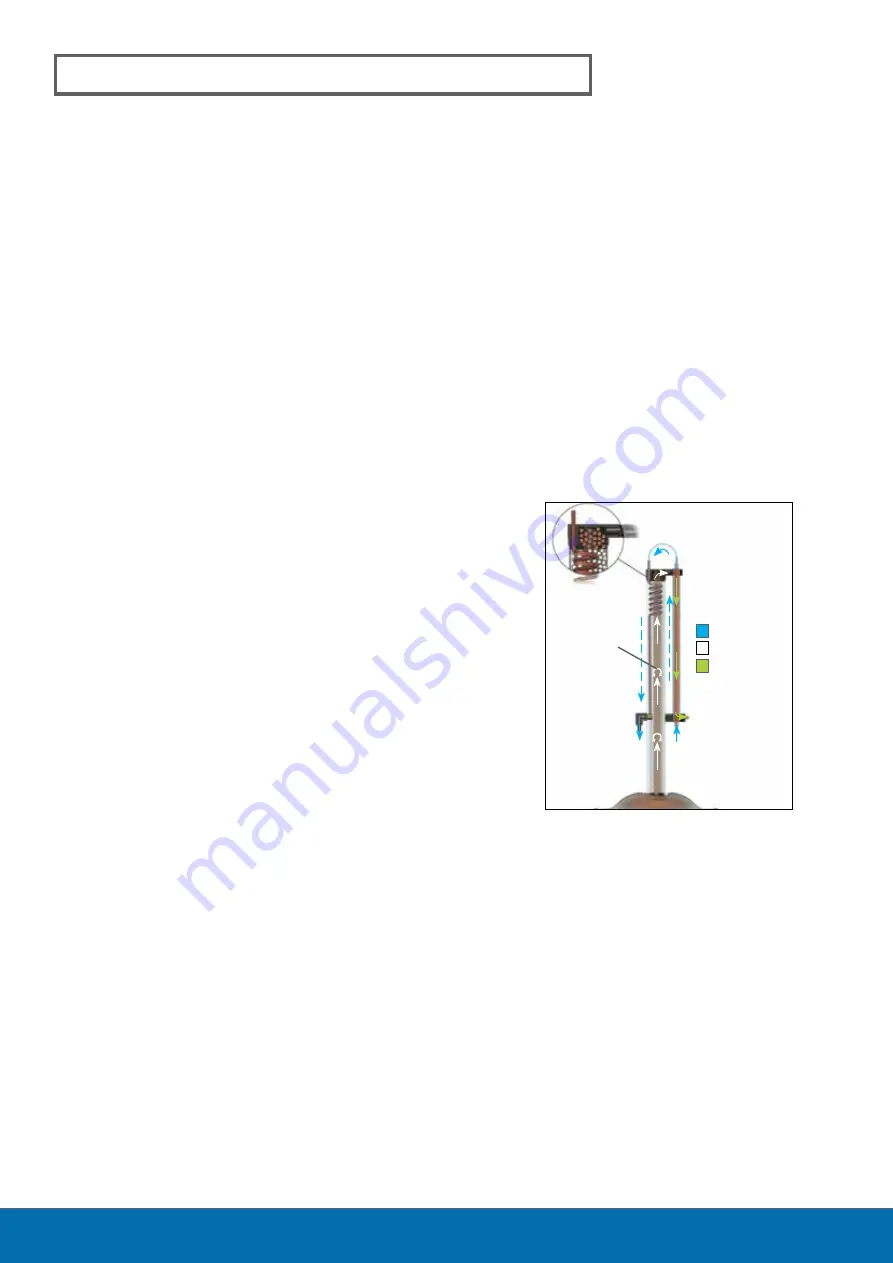

The saddles in the column provide a large surface

area to maximise the contact between the liquid and

vapour flows in the column, which accelerate the

refluxing action.

The Turbo 500 has been carefully engineered to

provide a continuously compensating reflux rate.

As the distillation process progresses, the alcohol

concentration in the wash reduces. To maintain high

purity of alcohol being produced, the refluxing ratio

will increase to compensate and the alcohol production

will slow. This slowing is most noticeable after two

hours of alcohol production.

Towards the end of the distillation the alcohol purity

remains high, but output will slow until it stops

altogether. At this point the water vapour will keep

rising and condensing part way up the column, but

nothing will reach the top of the column to pass into

the condenser. The alcohol extraction is finished at

that point.

HOW LONG CAN I KEEP A WASH FOR BEFORE DISTILLING IT?

We recommend distilling a wash within one week of

clearing. The longer it is left, the more off flavours may

develop caused by autolysis of the dead yeast cells. It is

likely to be fine for up to eight weeks if kept sealed

and cool.

HOW DOES DISTILLATION IN THE TURBO 500

DISTILLATION SYSTEM WORK?

The wash is heated in the boiler to boiling point

and kept at boiling point throughout the distillation

process. The vapour boiled off from the wash rises up

the column, in which the vapours of the heavier liquids

(water and heavier undesirable molecules) condense

and fall back down. The alcohol vapour, being lighter

than water vapour, is rising up to the top of the column

and condenses back in the condenser into a liquid

alcohol. This cycle of evaporation, rising and condensing,

is continuous and is described as refluxing.

SUPPLEMENTARY INFORMATION AND FAQS

water flow

alcohol vapour

alcohol liquid

refluxing

water

out

water

in

alcohol out