4

Operation

Driving

Driving with automatic guidance

There are two types of guidance systems:

• Mechanical guidance

• Inductive guidance

Mechanical guidance

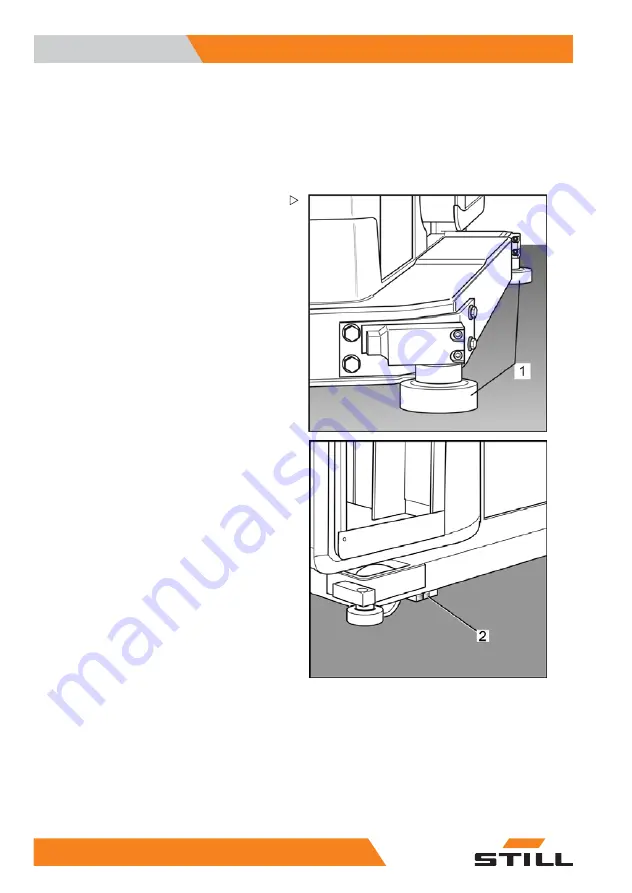

The mechanical guidance consists of one or

two rails, along with or in between the truck is

guided with permissible variation of 5 mm.

Entering the rack aisle

In order to enter the rail guidance, the truck

must be positioned as centrically as possible

and in alignment with the rack aisle in front of

the entering funnel.

The more carefully this positioning in front

of the rack aisle is done, the faster and the

gentler the lift truck can be moved into the

guidance. After the truck has been moved into

the guidance, the lateral rail switches (1) are

operated.

Through detection of the rail guide by means

of a rail switch (1), steering control is auto-

matically switched over to the new guidance

system

• For this, the driver’s left hand must make

contact with the steering knob / steering

wheel. When the controller recognizes the

hand contact it enables further functions.

• If you only wish to travel, the two-hand

control switch must be activated after

pressing the foot switch, and the control

lever "travel" deflected in the required

direction.

• If travel and raising/lowering are to be done

simultaneously, the control lever and the

operating rocker switch must be deflected

accordingly.

• Example: Pressing the operating rocker

switch on the right-hand side and pressing

the operating lever upwards results in main

lift up combined with forward drive. This

operating mode is known as diagonal travel.

62

5213 804 2501 EN - 01/2016

Summary of Contents for EK-X

Page 1: ...Original instructions High level order picker EK X 2131 2133 5213 804 2501 EN 01 2016 ...

Page 2: ......

Page 6: ......

Page 7: ...1 Foreword ...

Page 15: ...2 Safety ...

Page 30: ...2 Safety Personal protective equipment 24 5213 804 2501 EN 01 2016 ...

Page 31: ...3 Overview ...

Page 44: ...3 Overview Safety equipment 38 5213 804 2501 EN 01 2016 ...

Page 45: ...4 Operation ...

Page 86: ...4 Operation Emergency operation 80 5213 804 2501 EN 01 2016 ...

Page 87: ...5 Maintenance ...

Page 99: ...6 Technical data ...

Page 101: ...7 Special equipment ...

Page 119: ......