4

Use

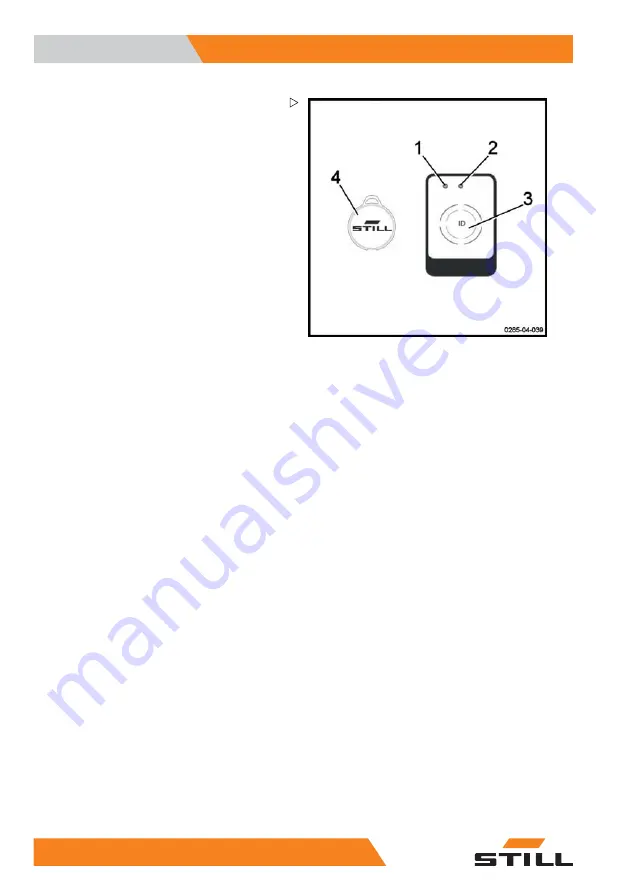

Operating the FleetManager™ option

Disconnecting a truck equipped with an

RFID reading device

– Park the truck in a safe place.

– Briefly place the RFID card or the RFID

transponder (4) in front of the reading device

(3).

The LED (1) lights up for a second (red colour).

The LED (2) is not lit. A long acoustic signal

sounds.

The LED (1) is no longer lit. The LED (2)

flashes slowly at two-second intervals (green

colour). No acoustic signal sounds.

The truck is disabled.

– Turn the switch key to the off position to

switch the truck off completely.

64

11638011651 EN - 09/2019

Summary of Contents for EXD-SF 20

Page 1: ...Original instructions Double pallet stacker EXD SF 20 0313 0346 11638011651 EN 09 2019 ...

Page 2: ......

Page 4: ......

Page 10: ......

Page 11: ...1 Introduction ...

Page 19: ...2 Safety ...

Page 28: ...2 Safety Safety tests 18 11638011651 EN 09 2019 ...

Page 29: ...3 Overviews ...

Page 40: ...3 Overviews Markings 30 11638011651 EN 09 2019 ...

Page 41: ...4 Use ...

Page 113: ...5 Maintenance ...

Page 139: ...6 Technical specifications ...

Page 140: ...6 Technical specifications EXD SF 20 datasheet EXD SF 20 datasheet 130 11638011651 EN 09 2019 ...

Page 148: ......

Page 149: ......

Page 150: ...STILL GmbH 11638011651 EN 09 2019 ...