Maintenance

5

Maintenance every 1000 hours

1

Hydraulic filter 20µm

2

Main pressure cut-off

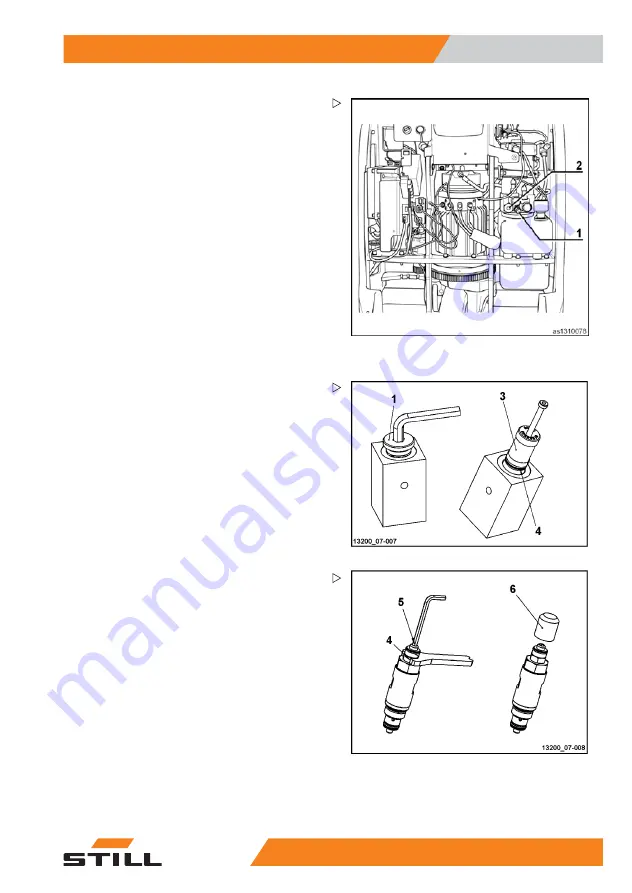

Changing the hydraulic pressure filter "1"

– Unscrew the plug (1).

– Insert an M6 type screw in the filter (3).

– Carefully remove the filter (3).

– Lubricate the O-ring (4) before changing the

filter element.

– Carefully fit the new filter and O-ring (see

illustration).

– Tighten the plug (1) to a torque of 70 Nm.

Adjusting the main pressure cut-off "2"

– Remove the safety plug (6).

– Unscrew the locknut (4).

– Adjust the pressure of the pressure cut-off

using an Allen key (5).

• To increase the pressure cut-off setting,

turn the key (5) clockwise.

• To lower the pressure cut-off setting, turn

the key (5) anti-clockwise.

– When the pressure cut-off setting is ad-

justed, lock the setting by tightening the

locknut (4).

1170 801 15 09 [EN]

111

Summary of Contents for EXG-10

Page 2: ......

Page 7: ...1 Introduction ...

Page 20: ...1 Introduction Environmental considerations 14 1170 801 15 09 EN ...

Page 21: ...2 Safety ...

Page 31: ...3 Overviews ...

Page 39: ...4 Use ...

Page 82: ...4 Use Putting Out of Commission and Storage 76 1170 801 15 09 EN ...

Page 83: ...5 Maintenance ...

Page 123: ...6 Technical data ...

Page 135: ......

Page 136: ...STILL GmbH Berzeliusstrasse 10 D 22113 Hamburg Ident no 1170 801 15 09 EN ...

Page 138: ......

Page 139: ...7 Diagrams ...

Page 146: ...7 Diagrams Electrical installation 140 1170 801 15 09 EN ...

Page 148: ...7 Diagrams Electrical installation 142 1170 801 15 09 EN ...

Page 150: ...7 Diagrams Electrical installation 144 1170 801 15 09 EN ...

Page 151: ...Diagrams 7 Electrical installation Mast tilt option EXG10 EXG12 EXG16 1170 801 15 09 EN 145 ...

Page 152: ...STILL GmbH Berzeliusstrasse 10 D 22113 Hamburg Ident no 1170 801 15 09 EN ...