Checking the anti-crush safety de-

vice

Anti-crush safety function

The machine moves in the opposite direction

when the anti-crush button (2) is pressed.

If the truck is being operated in narrow areas

(such as in a lift for example), the operator

may get stuck against the wall if care is not

taken. Without an anti-crush safety device, the

tiller could injure the operator.

The truck immediately moves off in the oppo-

site direction when the anti-crush device on

the tiller head comes into contact with the driv-

er's body. When the operator moves away

from the anti-crush safety device, the machine

stops even if a drive direction is selected

again.

Normal operation may be resumed after re-

leasing the drive switches.

Checking the anti-crush safety device

WARNING

Ensure that the test zone is free of people and ob-

jects, both in front of and behind the truck.

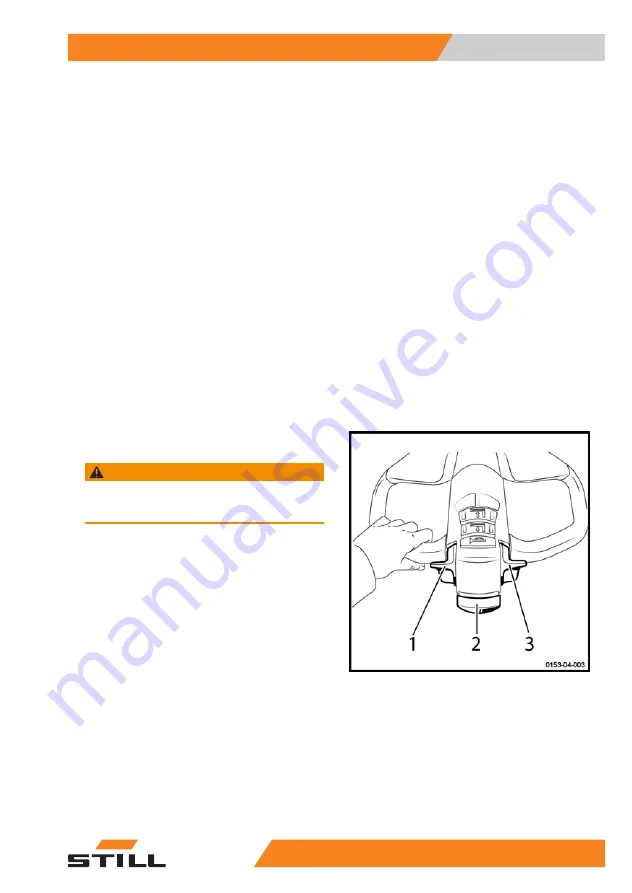

–

Move the drive switch (1) or (3) to move the

truck towards you.

–

Operate the anti-crush safety device (2).

The truck stops and accelerates in the oppo-

site drive direction.

–

Release the anti-crush safety button.

The truck stops.

Use

4

Checks and actions prior to commissioning

37

1152 801 15 17 EN - 02/2021 - 14

Summary of Contents for EXU-H-18

Page 2: ......

Page 4: ......

Page 10: ......

Page 11: ...1 Introduction ...

Page 20: ...Introduction 1 Disposing of components and batteries 10 1152 801 15 17 EN 02 2021 14 ...

Page 21: ...2 Safety ...

Page 31: ...3 Overviews ...

Page 40: ...Overviews 3 Markings 30 1152 801 15 17 EN 02 2021 14 ...

Page 41: ...4 Use ...

Page 94: ...Use 4 Handling the truck in specific situations 84 1152 801 15 17 EN 02 2021 14 ...

Page 95: ...5 Maintenance ...

Page 126: ...Maintenance 5 Commissioning and storage 116 1152 801 15 17 EN 02 2021 14 ...

Page 127: ...6 Technical specifications ...

Page 128: ...EXU H datasheet Technical specifications 6 EXU H datasheet 118 1152 801 15 17 EN 02 2021 14 ...

Page 140: ......

Page 141: ......