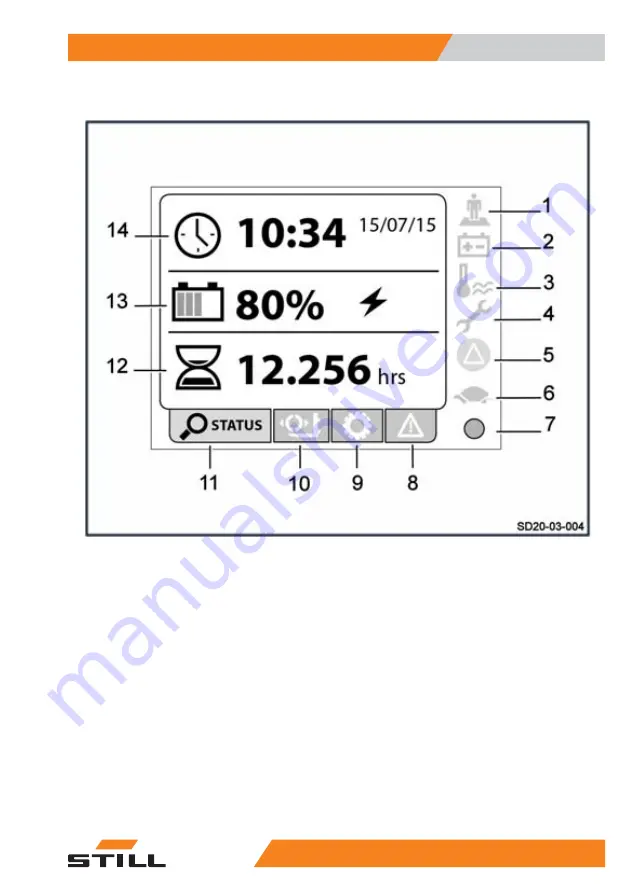

Display operating unit

Operator presence indicator light

Battery indicator light

Temperature indicator light

Settings indicator light

Warning indicator light

Drive programme indicator light

Activity indicator light

Error Code menu

1

2

3

4

5

6

7

8

Settings menu

Load Management and Drive wheel position

menu

Status menu

Display of the operating time of the truck

Display of the battery charge

Display of the date and time

9

10

11

12

13

14

For more information, refer to chapter 4 Using

the display operating unit.

Overviews

3

Operating and display devices

27

11748011551 EN - 02/2021 - 09

Summary of Contents for FXV 14 N

Page 2: ......

Page 4: ......

Page 10: ......

Page 11: ...1 Introduction ...

Page 20: ...Introduction 1 Disposing of components and batteries 10 11748011551 EN 02 2021 09 ...

Page 21: ...2 Safety ...

Page 31: ...3 Overviews ...

Page 40: ...Overviews 3 Markings 30 11748011551 EN 02 2021 09 ...

Page 41: ...4 Use ...

Page 115: ...5 Maintenance ...

Page 140: ...Maintenance 5 Storage and decommissioning 130 11748011551 EN 02 2021 09 ...

Page 141: ...6 Technical specifications ...

Page 150: ......

Page 151: ......