Operating the iGo neo

4

Operating the truck in ASSISTANCE mode

Switching on ASSISTANCE mode

Before

ASSISTANCE

mode is available,

the remote control must be activated and

ASSISTANCE

mode must be switched on.

=

1x 2 Sec.

1

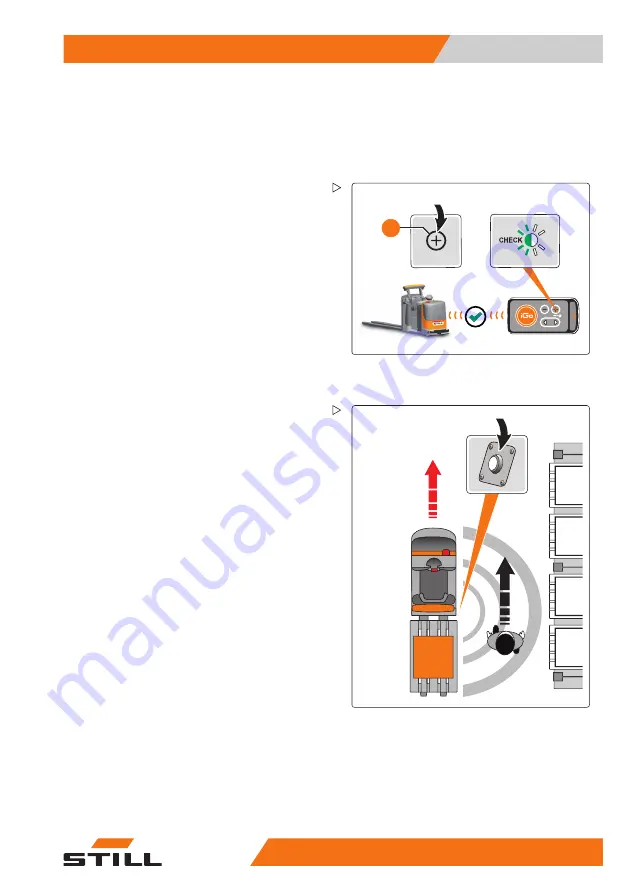

Activating the remote control

The connection between the truck and remote

control must first be established.

– Press the button (1) on the remote control

for two seconds.

If the CHECK indicator light flashes contin-

uously, there is a connection between the

remote control and truck.

The LED signalling unit shows the truck

alignment in the aisle (LEFT - MIDDLE -

RIGHT). The authorised service centre can

configure the preferred initial truck alignment.

1x

Switching on ASSISTANCE mode

– If necessary, the desired truck alignment

can be adjusted using the remote control

(see the following chapter "Adjusting the

truck alignment").

– Press the assistance buttons on the side

to which the truck is aligned to switch on

ASSISTANCE

mode.

Once

ASSISTANCE

mode has been

switched on, movement tracking is ACTIVE

immediately and is focused on the operator.

The truck follows the operator along the rack

contour.

50108046085 EN - 08/2017

57

Summary of Contents for iGo neo CX-20

Page 2: ......

Page 4: ......

Page 8: ......

Page 9: ...1 Foreword ...

Page 20: ...1 Foreword Environmental considerations 12 50108046085 EN 08 2017 ...

Page 21: ...2 Safety ...

Page 33: ...3 Components of the iGo neo ...

Page 50: ...3 Components of the iGo neo Remote control 42 50108046085 EN 08 2017 ...

Page 51: ...4 Operating the iGo neo ...

Page 82: ...4 Operating the iGo neo Operating the truck in ASSISTANCE mode 74 50108046085 EN 08 2017 ...

Page 83: ...5 Storage ...

Page 85: ...6 Cleaning ...

Page 89: ...7 Transporting ...

Page 92: ...7 Transporting Transporting the truck 84 50108046085 EN 08 2017 ...

Page 93: ...8 Maintenance ...

Page 98: ...8 Maintenance Maintenance 1000 hours annually 90 50108046085 EN 08 2017 ...

Page 99: ...9 Technical data ...

Page 110: ......

Page 111: ......

Page 112: ...STILL GmbH 50108046085 EN 08 2017 ...