4

Operating the iGo neo

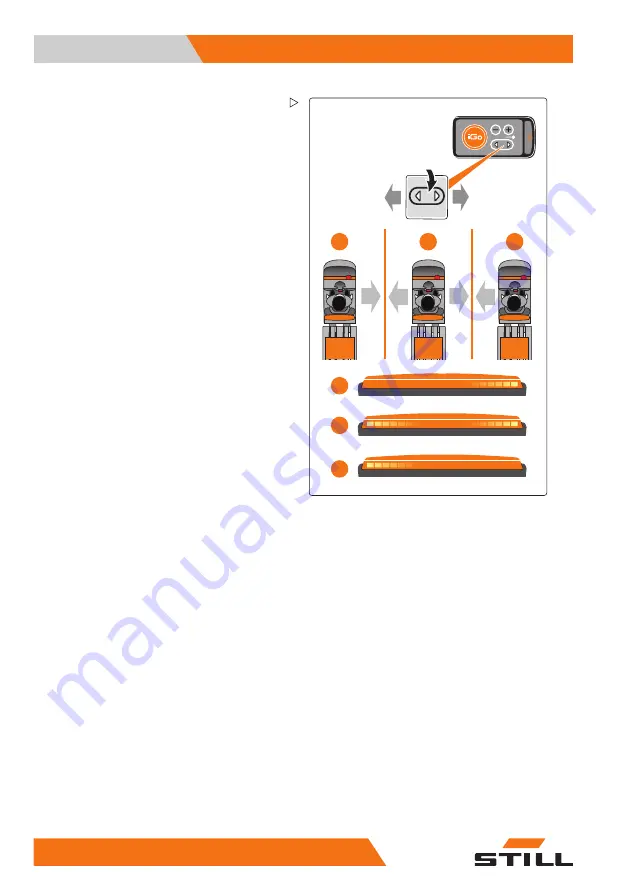

Operating the truck in ASSISTANCE mode

A B

1

2

3

1

2

3

Adjusting the truck alignment

Before order picking starts, the operator

specifies whether the truck must align to

the right (1), left (3) or to the centre (2) of

the aisle. In

ASSISTANCE

mode, the truck

then automatically follows the selected rack

contour.

The truck can only be set to an alignment for

which the truck has detected a corresponding

rack contour. If the selected alignment cannot

be set, the truck emits the "Truck alignment

not possible" warning sound (a warning sound

for one second).

– Adjust the truck alignment using the remote

control:

Button (A)

• Push once briefly: Switch the truck align-

ment in sequence (LEFT ► MIDDLE ►

RIGHT ► LEFT)

Button (B)

• Push once briefly: Switch the truck align-

ment in sequence (RIGHT ► MIDDLE ►

LEFT ► RIGHT)

The LED signalling unit signals the set truck

alignment:

• Truck alignment RIGHT (1)

• Truck alignment MIDDLE (2)

• Truck alignment LEFT (3)

If the desired truck alignment cannot be set,

the truck position must be corrected.

58

50108046085 EN - 08/2017

Summary of Contents for iGo neo CX-20

Page 2: ......

Page 4: ......

Page 8: ......

Page 9: ...1 Foreword ...

Page 20: ...1 Foreword Environmental considerations 12 50108046085 EN 08 2017 ...

Page 21: ...2 Safety ...

Page 33: ...3 Components of the iGo neo ...

Page 50: ...3 Components of the iGo neo Remote control 42 50108046085 EN 08 2017 ...

Page 51: ...4 Operating the iGo neo ...

Page 82: ...4 Operating the iGo neo Operating the truck in ASSISTANCE mode 74 50108046085 EN 08 2017 ...

Page 83: ...5 Storage ...

Page 85: ...6 Cleaning ...

Page 89: ...7 Transporting ...

Page 92: ...7 Transporting Transporting the truck 84 50108046085 EN 08 2017 ...

Page 93: ...8 Maintenance ...

Page 98: ...8 Maintenance Maintenance 1000 hours annually 90 50108046085 EN 08 2017 ...

Page 99: ...9 Technical data ...

Page 110: ......

Page 111: ......

Page 112: ...STILL GmbH 50108046085 EN 08 2017 ...