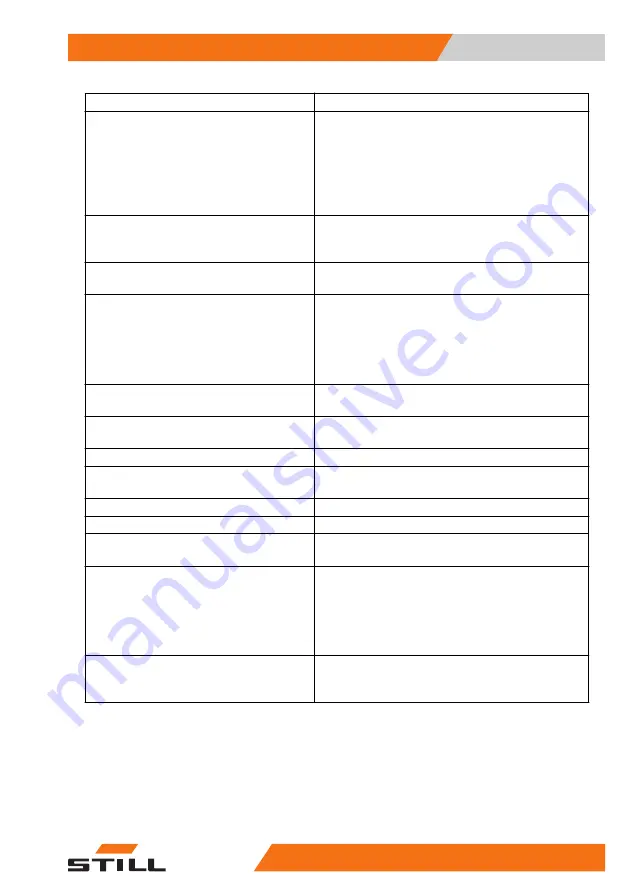

Component

Course of action

Attachments (variant)

Ensure that the attachments are mounted correctly

in accordance with the operating instructions from

the manufacturer.

Perform a visual inspection to ensure that the at-

tachments are intact and are leak-tight.

Perform checks to ensure the attachments are

working correctly.

Lift cylinders, tilt cylinders, tank, valve

block, hoses, pipes, connections

Visually inspect for damage and leakages.

Have damaged components replaced by the author-

ised service centre.

Underside

Check the area under the truck for leaking consum-

ables.

Wheels, tyres

Visually inspect for wear and damage.

Make sure that only rims of the same type from the

same manufacturer are fitted.

In the event of uneven tyre wear, replace both tyres.

Observe the safety regulations in the section enti-

tled "Tyres".

Axle

Make sure that no consumables are escaping from

the axle.

Overhead guard, guard grille (variant)

Visually inspect for sound condition.

Check for secure mounting.

Steps

Make sure they are clean (free of ice, not slippery).

Panes of glass (variant)

Visually inspect for sound condition.

Make sure they are clean (also free of ice).

Handholds

Check for secure mounting.

Maintenance lids

Check the close function and close.

Battery hood

Make sure that there are no unused bores in the

battery hood.

Battery door

Perform a visual inspection for integrity and defor-

mation.

Check that the interlock is in good condition and is

working correctly.

Check the close function.

Close.

Battery

Check that the interlock is in good condition and is

working correctly.

Lock the battery.

Operating

4

Checks and tasks before daily use

83

56368011501 EN - 04/2022 - 13

Summary of Contents for RX20 14-20

Page 2: ......

Page 16: ......

Page 17: ...1 Foreword ...

Page 25: ...Foreword 1 Your truck 9 56368011501 EN 04 2022 13 ...

Page 45: ...2 Safety ...

Page 63: ...Safety 2 Residual risk 47 56368011501 EN 04 2022 13 ...

Page 78: ...Safety 2 Emissions 62 56368011501 EN 04 2022 13 ...

Page 79: ...3 Overviews ...

Page 80: ...Overview Overviews 3 Overview 64 56368011501 EN 04 2022 13 ...

Page 82: ...Driver s compartment Overviews 3 Driver s compartment 66 56368011501 EN 04 2022 13 ...

Page 97: ...4 Operating ...

Page 518: ...Operating 4 Decommissioning 502 56368011501 EN 04 2022 13 ...

Page 519: ...5 Maintenance ...

Page 547: ...Maintenance 5 Preserving operational readiness 531 56368011501 EN 04 2022 13 ...

Page 554: ...Maintenance 5 1000 hour maintenance annual maintenance 538 56368011501 EN 04 2022 13 ...

Page 555: ...6 Technical data ...

Page 599: ......