NOTE

The pictograms are affixed according to the

attachment fitted at the factory. If an attach-

ment with different functions is fitted, the au-

thorised service centre must check that the

pictograms bear the correct representation

and must change them if necessary.

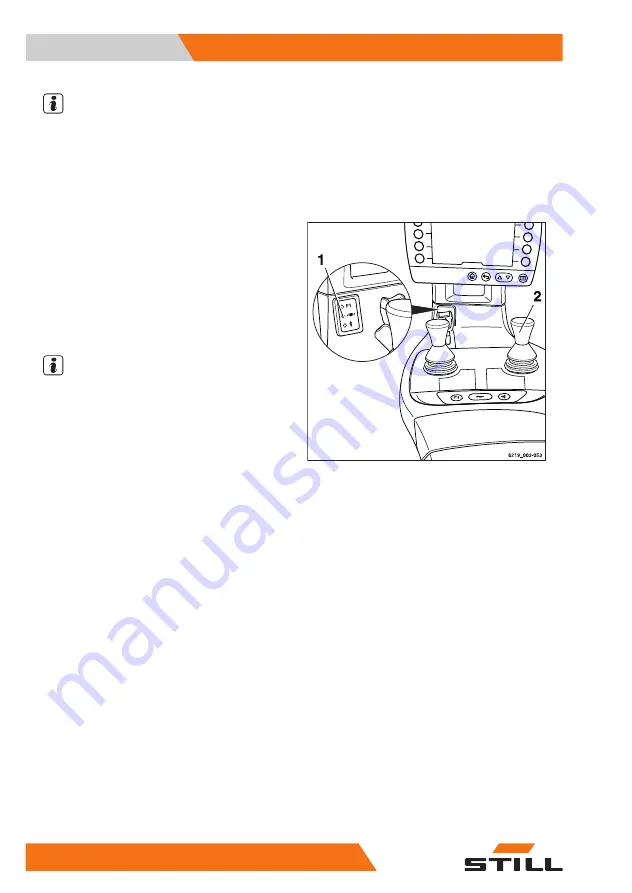

Clamp locking mechanism

–

To release the clamp locking mechanism,

push the operating lever (2) forwards.

The clamp locking mechanism is released.

The LED for the "clamp release" (1) lights up

and remains lit while the clamp locking mech-

anism is released.

NOTE

The hydraulic function for opening the clamp

is available for one second after the clamp

locking mechanism is released. After one sec-

ond, the clamp locking mechanism is automat-

ically reactivated.

–

To open the clamp, push the operating lev-

er (2) forwards again.

It is not necessary to release the clamp lock-

ing mechanism in order to close the clamp.

–

To close the clamp, pull the operating lev-

er (2) backwards.

Operating

4

Attachments

324

56368011501 EN - 04/2022 - 13

Summary of Contents for RX20 14-20

Page 2: ......

Page 16: ......

Page 17: ...1 Foreword ...

Page 25: ...Foreword 1 Your truck 9 56368011501 EN 04 2022 13 ...

Page 45: ...2 Safety ...

Page 63: ...Safety 2 Residual risk 47 56368011501 EN 04 2022 13 ...

Page 78: ...Safety 2 Emissions 62 56368011501 EN 04 2022 13 ...

Page 79: ...3 Overviews ...

Page 80: ...Overview Overviews 3 Overview 64 56368011501 EN 04 2022 13 ...

Page 82: ...Driver s compartment Overviews 3 Driver s compartment 66 56368011501 EN 04 2022 13 ...

Page 97: ...4 Operating ...

Page 518: ...Operating 4 Decommissioning 502 56368011501 EN 04 2022 13 ...

Page 519: ...5 Maintenance ...

Page 547: ...Maintenance 5 Preserving operational readiness 531 56368011501 EN 04 2022 13 ...

Page 554: ...Maintenance 5 1000 hour maintenance annual maintenance 538 56368011501 EN 04 2022 13 ...

Page 555: ...6 Technical data ...

Page 599: ......