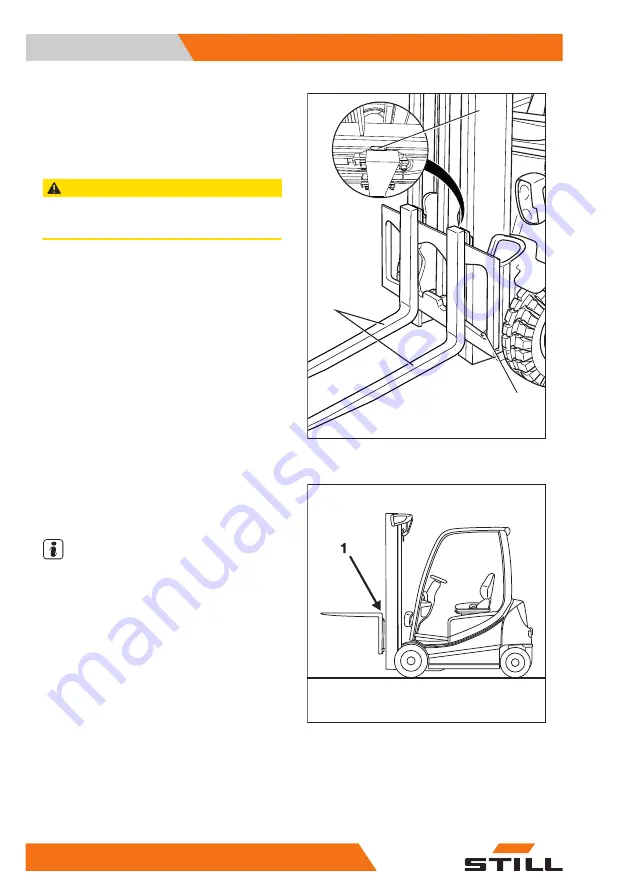

Checking the fork arms

–

Check the fork arms (1) for any visible de-

formation. Wear must not amount to more

than 10% of the original thickness.

CAUTION

Risk of component damage!

Always replace worn fork arms in pairs.

–

Check that the fork latch (3) is functioning

correctly.

–

Make sure that the locking screw (2) is

present and cannot fall out.

Checking the reversible fork

arms

NOTE

This check is only required for reversible fork

arms (variant).

–

Check the outside of the fork bend (1) for

cracks. Contact your service centre.

2

1

3

Maintenance

5

1000-hour maintenance/annual maintenance

536

56368011501 EN - 04/2022 - 13

Summary of Contents for RX20 14-20

Page 2: ......

Page 16: ......

Page 17: ...1 Foreword ...

Page 25: ...Foreword 1 Your truck 9 56368011501 EN 04 2022 13 ...

Page 45: ...2 Safety ...

Page 63: ...Safety 2 Residual risk 47 56368011501 EN 04 2022 13 ...

Page 78: ...Safety 2 Emissions 62 56368011501 EN 04 2022 13 ...

Page 79: ...3 Overviews ...

Page 80: ...Overview Overviews 3 Overview 64 56368011501 EN 04 2022 13 ...

Page 82: ...Driver s compartment Overviews 3 Driver s compartment 66 56368011501 EN 04 2022 13 ...

Page 97: ...4 Operating ...

Page 518: ...Operating 4 Decommissioning 502 56368011501 EN 04 2022 13 ...

Page 519: ...5 Maintenance ...

Page 547: ...Maintenance 5 Preserving operational readiness 531 56368011501 EN 04 2022 13 ...

Page 554: ...Maintenance 5 1000 hour maintenance annual maintenance 538 56368011501 EN 04 2022 13 ...

Page 555: ...6 Technical data ...

Page 599: ......