Checks and tasks before daily use

Visual inspections and function checking

WARNING

Risk of injury from falling off the truck!

When climbing onto the truck, there is

a risk of getting stuck or slipping and

falling. Use suitable equipment to reach

higher points on the truck.

–

Use only the steps provided for this

purpose to climb onto the truck.

–

Use equipment such as stepladders

or platforms to reach inaccessible

areas.

Damage to the truck or the attachment (var-

iant), non-functional switches or safety sys-

tems and modification of predefined set val-

ues can lead to unpredictable and dangerous

situations. To ensure that the truck is operat-

ed safely, the visual inspections and function

checking must be carried out before daily use.

The following table lists the components that

must be checked and the inspection points of

these components. If damage or other defects

are identified on the truck or the attachment

(variant) during the following inspections, the

truck must not be used until it has been prop-

erly repaired. Damage or other defects must

be reported to the supervisor or the responsi-

ble fleet manager immediately so that repairs

by the authorised service centre can be ar-

ranged.

Ensure that the truck is safe for operation each day before it is used:

Component

Course of action

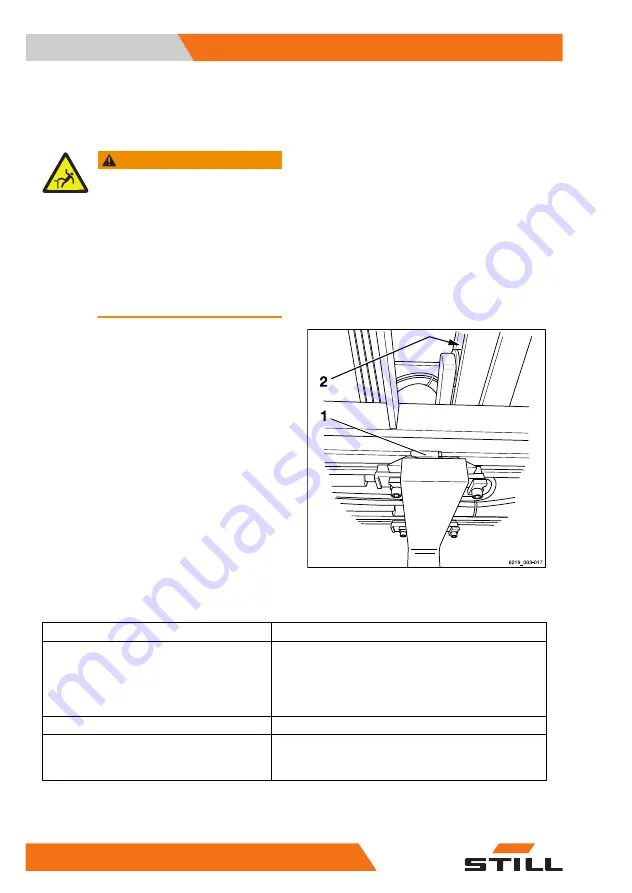

Fork arms, general lifting accessories

Perform a visual inspection to check for deformation

and wear (e.g. to check if they are bent, broken or

feature significant wear).

Check the condition and function of the safety devi-

ces (1) to prevent lifting and shifting.

Roller tracks (2)

Make sure that there is a film of grease.

Load chains

Perform a visual inspection to ensure that the

chains are intact and have adequate and even ten-

sion.

Fork arms and roller tracks

Operating

4

Checks and tasks before daily use

82

56368011501 EN - 04/2022 - 13

Summary of Contents for RX20 14-20

Page 2: ......

Page 16: ......

Page 17: ...1 Foreword ...

Page 25: ...Foreword 1 Your truck 9 56368011501 EN 04 2022 13 ...

Page 45: ...2 Safety ...

Page 63: ...Safety 2 Residual risk 47 56368011501 EN 04 2022 13 ...

Page 78: ...Safety 2 Emissions 62 56368011501 EN 04 2022 13 ...

Page 79: ...3 Overviews ...

Page 80: ...Overview Overviews 3 Overview 64 56368011501 EN 04 2022 13 ...

Page 82: ...Driver s compartment Overviews 3 Driver s compartment 66 56368011501 EN 04 2022 13 ...

Page 97: ...4 Operating ...

Page 518: ...Operating 4 Decommissioning 502 56368011501 EN 04 2022 13 ...

Page 519: ...5 Maintenance ...

Page 547: ...Maintenance 5 Preserving operational readiness 531 56368011501 EN 04 2022 13 ...

Page 554: ...Maintenance 5 1000 hour maintenance annual maintenance 538 56368011501 EN 04 2022 13 ...

Page 555: ...6 Technical data ...

Page 599: ......