Operation

5

Handling the battery

6210_003-012

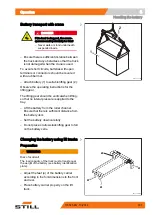

1

2

Battery transport with crane

DANGER

If the load is dropped, the conse-

quences could potentially be fatal!

– Never walk or stand underneath

suspended loads.

– Ensure there is sufficient distance between

the truck and any obstacles so that the truck

is not damaged when the crane is used.

To avoid short circuits, batteries with open

terminals or connectors should be covered

with a rubber mat.

– Attach battery (1) to suitable lifting gear (2).

Observe the operating instructions for the

lifting gear.

The lifting gear should be vertical when lifting,

so that no lateral pressure is applied to the

tray.

– Lift the battery from the roller channel.

Ensure that there is sufficient distance from

the battery door.

– Set the battery down carefully.

– Do not place or allow slack lifting gear to fall

on the battery cells.

6210_003-013

a

a

a

a

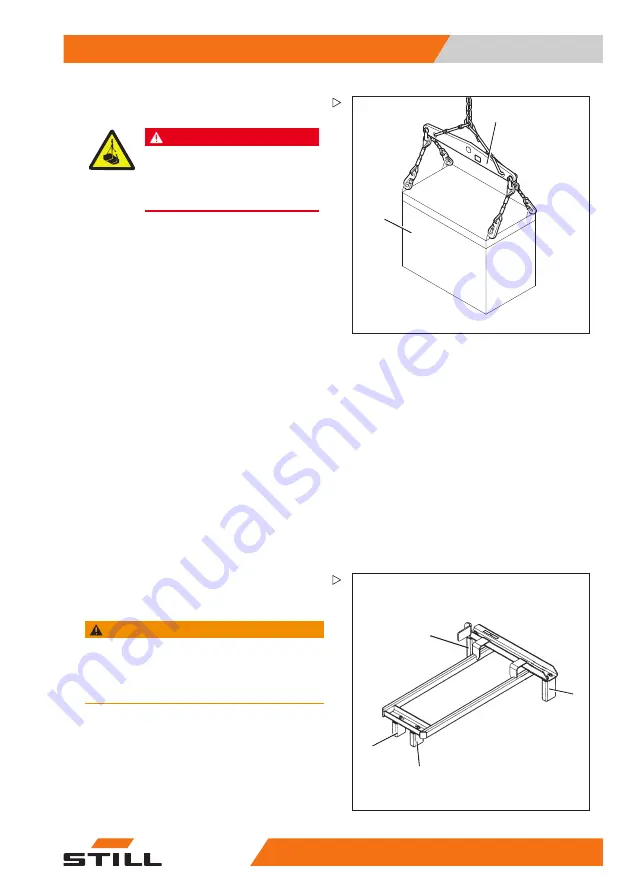

Changing the battery using lift trucks

Preparation

WARNING

Risk of accident!

The load capacity of the truck must at least equal

the weight of the battery (see battery identification

plate).

– Adjust the feet (a) of the battery carrier

according to the fork dimensions to the front

and rear.

– Place battery carrier properly on the lift

truck.

170525 EN - 10/2016

301

Summary of Contents for RX60-16

Page 2: ......

Page 4: ......

Page 13: ...1 Foreword ...

Page 24: ...1 Foreword Environmental considerations 12 170525 EN 10 2016 ...

Page 25: ...2 Introduction ...

Page 37: ...3 Safety ...

Page 58: ...3 Safety Emissions 46 170525 EN 10 2016 ...

Page 59: ...4 Overviews ...

Page 61: ...Overviews 4 General view of truck 170525 EN 10 2016 49 ...

Page 81: ...5 Operation ...

Page 344: ...5 Operation Cleaning 332 170525 EN 10 2016 ...

Page 345: ...6 Maintenance ...

Page 348: ...6 Maintenance General maintenance information 336 170525 EN 10 2016 ...

Page 352: ...6 Maintenance General maintenance information 340 170525 EN 10 2016 ...

Page 389: ...7 Technical data ...

Page 410: ......

Page 411: ......

Page 412: ...STILL GmbH 170525 EN 10 2016 ...