5

Operation

Handling the battery

• Mechanical battery carrier (variant); see

⇒ Chapter "Battery replacement using the

mechanical battery carrier", P. 5-307.

• Hydraulic battery carrier (variant); see

⇒ Chapter "Replacing the battery with the

hydraulic battery carrier", P. 5-312

The load capacity of the lifting accessory used

must at least match the battery weight (see

battery identification plate).

6210_606-011

A

B

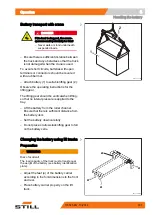

Replacing the battery using a forklift

truck

Preparation

WARNING

Risk of accident!

The load capacity of the truck used must at least

match the battery weight (see battery identification

plate).

– Before taking up the battery, adjust the fork

arms to match the cutout in the chassis (A).

Move the fork arms together, selecting the

maximum possible distance.

The fork arms must not be moved under the

battery any further than the length of the cutout

of the chassis (B = max. 850 mm).

It is useful to mark this measurement—mea-

sured from the fork tips—on the fork arms.

296

170525 EN - 10/2016

Summary of Contents for RX60-16

Page 2: ......

Page 4: ......

Page 13: ...1 Foreword ...

Page 24: ...1 Foreword Environmental considerations 12 170525 EN 10 2016 ...

Page 25: ...2 Introduction ...

Page 37: ...3 Safety ...

Page 58: ...3 Safety Emissions 46 170525 EN 10 2016 ...

Page 59: ...4 Overviews ...

Page 61: ...Overviews 4 General view of truck 170525 EN 10 2016 49 ...

Page 81: ...5 Operation ...

Page 344: ...5 Operation Cleaning 332 170525 EN 10 2016 ...

Page 345: ...6 Maintenance ...

Page 348: ...6 Maintenance General maintenance information 336 170525 EN 10 2016 ...

Page 352: ...6 Maintenance General maintenance information 340 170525 EN 10 2016 ...

Page 389: ...7 Technical data ...

Page 410: ......

Page 411: ......

Page 412: ...STILL GmbH 170525 EN 10 2016 ...