Maintenance

6

Maintenance

– Connect the battery male connector.

Checking the hydraulic system for

leaks

WARNING

Hydraulic oil under pressure can

escape from leaking lines and cause

injuries to the skin.

Wear suitable protective gloves,

industrial goggles etc.

WARNING

Hydraulic hoses become brittle!

Hydraulic hoses should not be used longer than 6

years.

The specifications of BGR 237 should be complied

with. Deviating national laws are to be taken into

account.

– Check pipe and hose connection screw

joints for leaks (traces of oil).

Hose lines must be changed if:

• The outer layer has been breached or

becomes brittle with tears

• They are leaking

• There are unnatural deformations (e.g.

bubble formation or buckling)

• A fitting is detached from the hose

• A fitting is badly damaged or corroded

Pipes must be changed if:

• There is abrasion with the loss of material

• There are unnatural deformations and

detectable bending stress

• They are leaking

170525 EN - 10/2016

365

Summary of Contents for RX60-16

Page 2: ......

Page 4: ......

Page 13: ...1 Foreword ...

Page 24: ...1 Foreword Environmental considerations 12 170525 EN 10 2016 ...

Page 25: ...2 Introduction ...

Page 37: ...3 Safety ...

Page 58: ...3 Safety Emissions 46 170525 EN 10 2016 ...

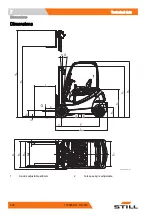

Page 59: ...4 Overviews ...

Page 61: ...Overviews 4 General view of truck 170525 EN 10 2016 49 ...

Page 81: ...5 Operation ...

Page 344: ...5 Operation Cleaning 332 170525 EN 10 2016 ...

Page 345: ...6 Maintenance ...

Page 348: ...6 Maintenance General maintenance information 336 170525 EN 10 2016 ...

Page 352: ...6 Maintenance General maintenance information 340 170525 EN 10 2016 ...

Page 389: ...7 Technical data ...

Page 410: ......

Page 411: ......

Page 412: ...STILL GmbH 170525 EN 10 2016 ...