6

Maintenance

1000-hour maintenance / Annual maintenance

6210_003-049_V2

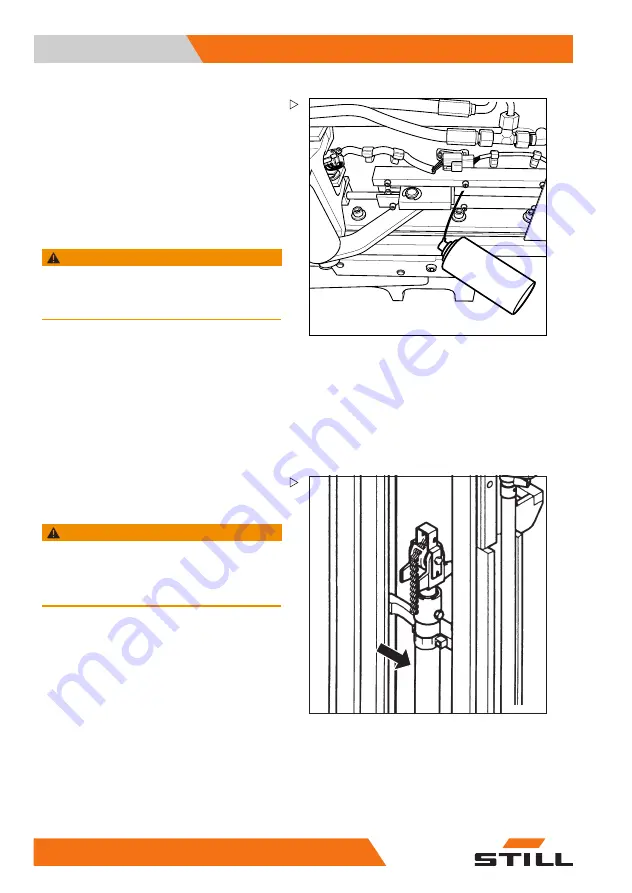

– Lubricate the catch rails with oil according

to the maintenance data table - do not use

grease!

– Connect the battery male connector.

– Pull the emergency off switch.

– Switch on the key switch.

– Retract the battery carrier fully and then

extend again.

WARNING

Risk of crushing!

The support rollers must be swung out fully and

locked in position after lubrication.

– Check that the support rollers are swung all

the way out and are locked in position.

– If the support rollers are fully swung out and

locked, reinstall the battery.

– If the support rollers do not swing out

correctly or are not in the locked position,

inform your authorised service centre.

7094_810-004

Checking the lift cylinders and

connections for leaks

WARNING

Risk of injury

Observe safety regulations for working on the lift

mast, see the "Working at the front of the truck"

chapter.

– Check the hydraulic connections and lift

cylinder for leaks (visual inspection).

– Have leaking screw joints or leaking hy-

draulic cylinders repaired by the authorised

service centre.

374

170525 EN - 10/2016

Summary of Contents for RX60-16

Page 2: ......

Page 4: ......

Page 13: ...1 Foreword ...

Page 24: ...1 Foreword Environmental considerations 12 170525 EN 10 2016 ...

Page 25: ...2 Introduction ...

Page 37: ...3 Safety ...

Page 58: ...3 Safety Emissions 46 170525 EN 10 2016 ...

Page 59: ...4 Overviews ...

Page 61: ...Overviews 4 General view of truck 170525 EN 10 2016 49 ...

Page 81: ...5 Operation ...

Page 344: ...5 Operation Cleaning 332 170525 EN 10 2016 ...

Page 345: ...6 Maintenance ...

Page 348: ...6 Maintenance General maintenance information 336 170525 EN 10 2016 ...

Page 352: ...6 Maintenance General maintenance information 340 170525 EN 10 2016 ...

Page 389: ...7 Technical data ...

Page 410: ......

Page 411: ......

Page 412: ...STILL GmbH 170525 EN 10 2016 ...