–

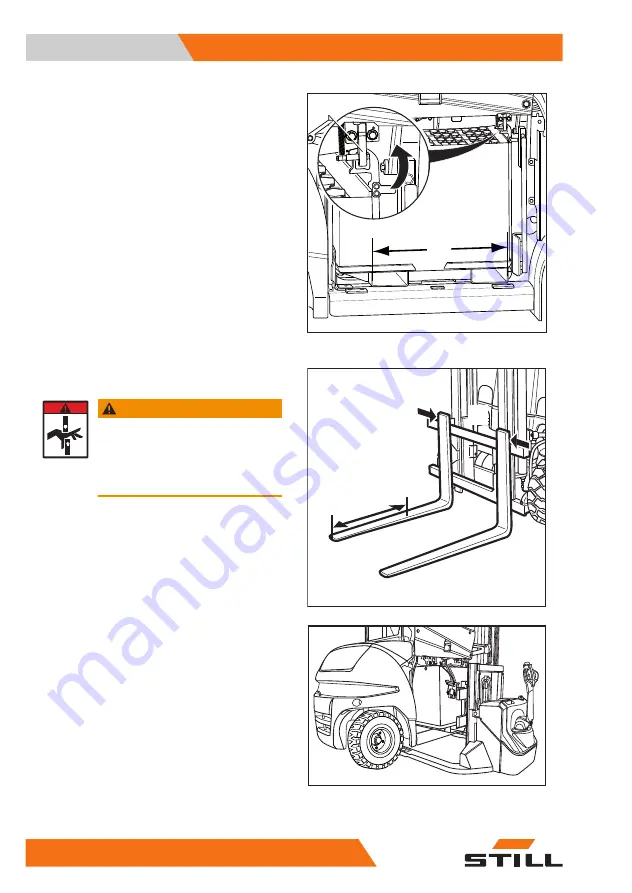

Adjust the distance (A) between the fork

arms of the lifting accessory to match the

distance (A) between the forked fittings in

the battery base frame.

–

Swivel the battery lock (1) upwards.

The battery lock is held in the raised position

by means of the tension spring. The battery

can be accessed as required.

Taking up the battery

WARNING

Risk of crushing/shearing!

Personnel must not stand directly next to

the battery or between the battery and

the truck when removing and inserting

the battery with the truck.

–

Determine the length of the battery base

frame and, starting from the fork tip, mark

one of the fork arms; dimension (B).

–

Move the fork arms carefully up to the mark

in the forked fittings in the battery base

frame.

–

Carefully lift the battery and battery base

frame up and out of the truck. When doing

so, pay attention to the distance to the

chassis.

–

Carefully remove the battery and the battery

base frame from the truck, i.e. at a low

speed, using slow steering movements and

braking carefully.

6341_003-009_V2

A

1

6210_606-011

A

B

Operating

4

Replacing and transporting the battery

290

56358042501 EN - - 11

Summary of Contents for RX60-60

Page 2: ......

Page 13: ...1 Foreword ...

Page 20: ...Overview Foreword 1 Your truck 8 56358042501 EN 11 ...

Page 41: ...2 Safety ...

Page 70: ...Safety 2 Emissions 58 56358042501 EN 11 ...

Page 71: ...3 Overviews ...

Page 83: ...4 Operating ...

Page 336: ...Operating 4 Decommissioning 324 56358042501 EN 11 ...

Page 337: ...5 Maintenance ...

Page 344: ...Maintenance 5 General maintenance information 332 56358042501 EN 11 ...

Page 381: ...6 1000 hour maintenance annual mainte nance ...

Page 385: ...7 Technical data ...

Page 398: ...Technical data 7 Fuse assignment 386 56358042501 EN 11 ...

Page 407: ......

Page 408: ...STILL GmbH 56358042501 EN 11 ...