–

Move the locking lever (3) into a vertical po-

sition.

It must be possible to move the fork arm.

–

Move the locking lever into a horizontal po-

sition.

The latch must engage in a recess on the fork

carriage. It must not be possible to move the

fork arm.

–

Replace faulty fork latches.

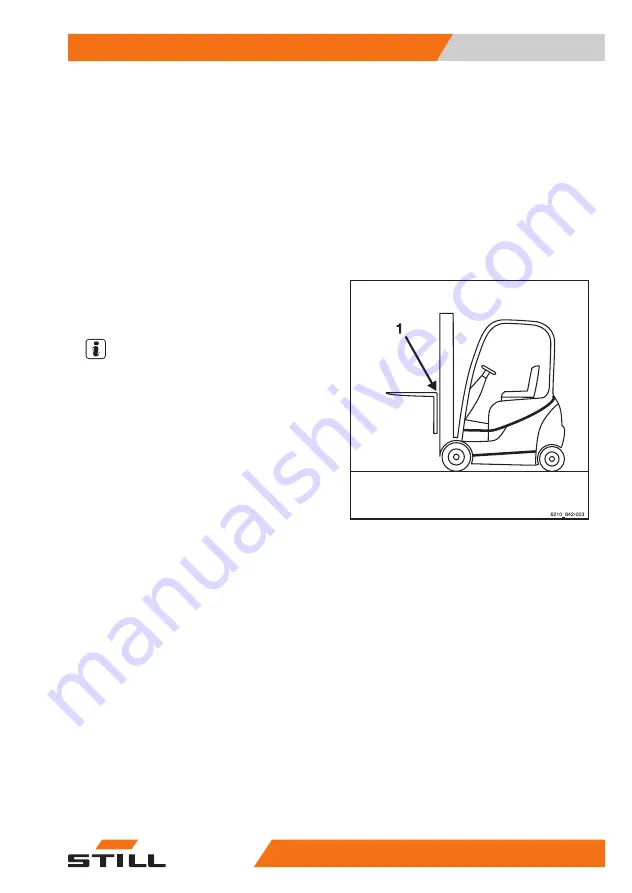

Checking the reversible fork

arms

NOTE

This check is only required for reversible fork

arms (variant).

–

Check the outside of the fork bend (1) for

cracks. Contact your service centre.

1000-hour maintenance/annual maintenance

6

Checking the reversible fork arms

371

56358042501 EN - - 11

Summary of Contents for RX60-60

Page 2: ......

Page 13: ...1 Foreword ...

Page 20: ...Overview Foreword 1 Your truck 8 56358042501 EN 11 ...

Page 41: ...2 Safety ...

Page 70: ...Safety 2 Emissions 58 56358042501 EN 11 ...

Page 71: ...3 Overviews ...

Page 83: ...4 Operating ...

Page 336: ...Operating 4 Decommissioning 324 56358042501 EN 11 ...

Page 337: ...5 Maintenance ...

Page 344: ...Maintenance 5 General maintenance information 332 56358042501 EN 11 ...

Page 381: ...6 1000 hour maintenance annual mainte nance ...

Page 385: ...7 Technical data ...

Page 398: ...Technical data 7 Fuse assignment 386 56358042501 EN 11 ...

Page 407: ......

Page 408: ...STILL GmbH 56358042501 EN 11 ...