●

Battery door hinges or battery cover hinges

●

Lubricate shafts and joints in dual-pedal op-

eration (variant)

Maintaining the seat belt

DANGER

There is a risk to life if the seat belt fails during an

accident!

If the seat belt is faulty, it may tear or open during an

accident and no longer keep the driver in the driver's

seat. The driver may therefore be hurled against the

truck components or out of the truck.

–

Ensure operational reliability by continually test-

ing.

–

Do not use a truck with a defective seat belt.

–

Only have a defective belt replaced by your serv-

ice centre.

–

Only use genuine spare parts.

–

Do not make any changes to the belt.

NOTE

Carry out the following checks on a regular

basis (monthly). In the case of significant

strain, a daily check is necessary.

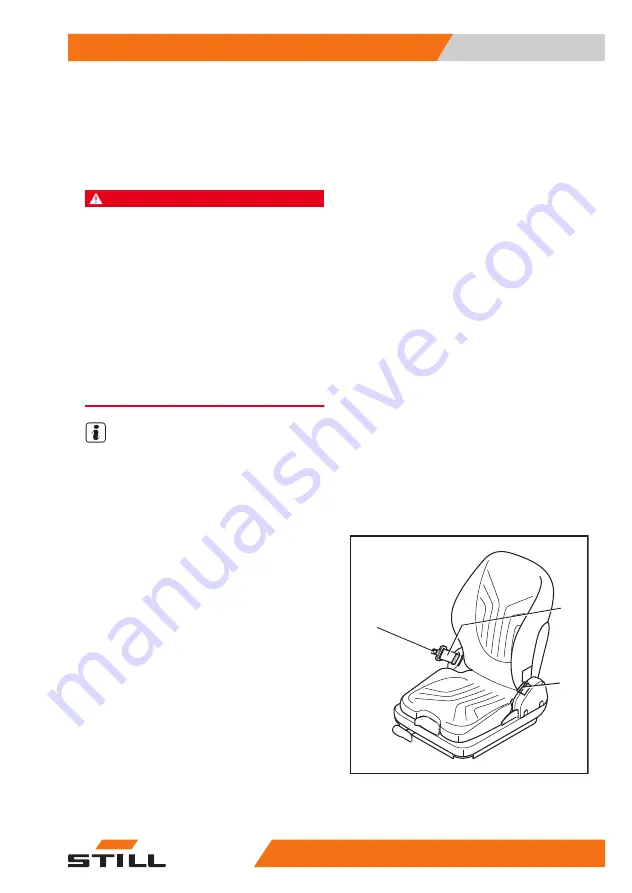

Checking the seat belt

–

Pull out the belt (3) completely and check

for wear.

The belt must not be frayed or cut. The stitch-

ing must not be loose.

–

Check whether the belt is dirty.

–

Check whether parts are worn or damaged,

including the attachment points.

–

Check the buckle (1) to ensure that it locks

in properly.

When the belt tongue (2) is inserted, the belt

must be held securely.

6327_342-009

1

2

3

Maintenance

5

Preserving operational readiness

355

56358042501 EN - - 11

Summary of Contents for RX60-60

Page 2: ......

Page 13: ...1 Foreword ...

Page 20: ...Overview Foreword 1 Your truck 8 56358042501 EN 11 ...

Page 41: ...2 Safety ...

Page 70: ...Safety 2 Emissions 58 56358042501 EN 11 ...

Page 71: ...3 Overviews ...

Page 83: ...4 Operating ...

Page 336: ...Operating 4 Decommissioning 324 56358042501 EN 11 ...

Page 337: ...5 Maintenance ...

Page 344: ...Maintenance 5 General maintenance information 332 56358042501 EN 11 ...

Page 381: ...6 1000 hour maintenance annual mainte nance ...

Page 385: ...7 Technical data ...

Page 398: ...Technical data 7 Fuse assignment 386 56358042501 EN 11 ...

Page 407: ......

Page 408: ...STILL GmbH 56358042501 EN 11 ...