Maintenance

5

Remaining ready for operation

7081_003-059

3

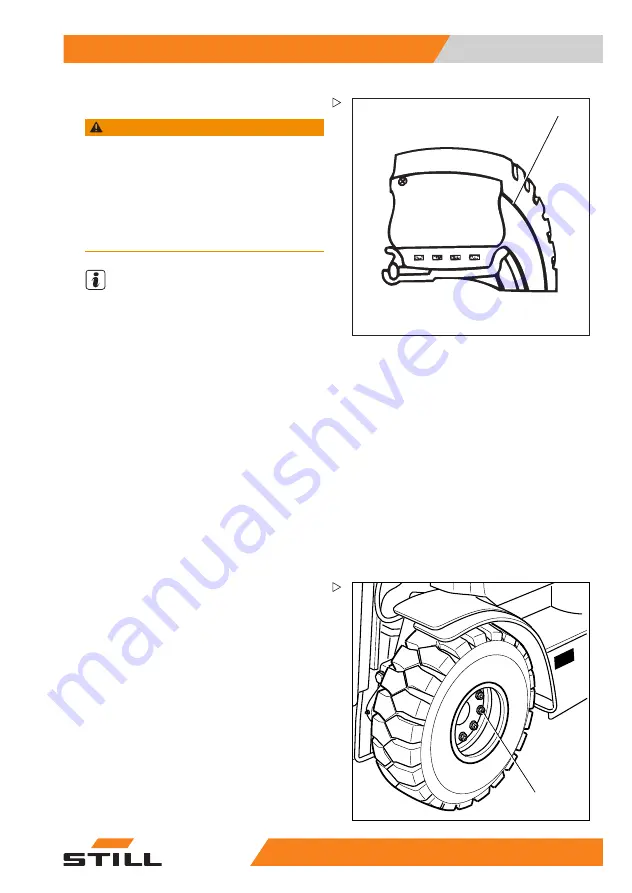

Checking condition and wear of the tyres

WARNING

Tyre quality affects the stability and handling of the

truck.

Changes can only be made in consultation with the

manufacturer.

When changing wheels or tyres, always ensure that

this does not cause the truck to tilt to one side (e.g.

always change right and left wheels at the same

time).

NOTE

The wear of the tyres on an axle must be

approximately the same.

•

The tread depth (1) for pneumatic tyres

must be at least 1.6 mm at every point on

the tread.

•

Super-elastic tyres (variant) can be worn

down to the wear mark (3).

– Check the tread depth on all four tyres.

– Check distance between the tyre tread and

the wear mark.

– Remove any foreign bodies imbedded in

the tyre tread.

Checking wheel fastenings

– Check that the wheel fastening (4) is se-

curely fastened and retighten as necessary.

4

7321_003-112

– Observe the torques; see the "maintenance

data table".

174749 EN - 03/2017

333

Summary of Contents for RX70-16

Page 1: ...Original instructions Diesel truck RX70 16 RX70 18 RX70 20 7311 7312 7313 174749 EN 03 2017 ...

Page 2: ......

Page 4: ......

Page 13: ...1 Foreword ...

Page 35: ...2 Safety ...

Page 49: ...Safety 2 Residual risk 174749 EN 03 2017 37 ...

Page 67: ...3 Overviews ...

Page 78: ...3 Overviews Operating and display elements 66 174749 EN 03 2017 ...

Page 79: ...4 Operation ...

Page 310: ...4 Operation Shutdown 298 174749 EN 03 2017 ...

Page 311: ...5 Maintenance ...

Page 318: ...5 Maintenance General maintenance information 306 174749 EN 03 2017 ...

Page 322: ...5 Maintenance General maintenance information 310 174749 EN 03 2017 ...

Page 354: ...5 Maintenance Remaining ready for operation 342 174749 EN 03 2017 ...

Page 359: ...6 Technical data ...

Page 367: ...Technical data 6 Ergonomic dimensions 174749 EN 03 2017 355 ...

Page 378: ......

Page 379: ......

Page 380: ...STILL GmbH 174749 EN 03 2017 ...