Operation

4

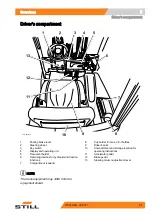

Testing and activities before daily use

Unit

Component

Course of action

Hydraulics

Lift and tilt cylinders, tank, valve

block, hoses, pipes, connections

Perform a visual inspection for damage

and leaks.

Check the area under the forklift truck

for leaking consumables.

Damaged hoses must be replaced by

the authorised service centre.

Wheels, tyres

Perform a visual inspection for wear

and damage.

Make sure that only rims of the same

type from the same manufacturer are

fitted.

In the event of uneven tyre wear,

replace both tyres.

Observe the safety regulations in the

chapter entitled "Tyres".

Chassis frame

Axle

Make sure that no consumables are

escaping from the axle.

– Do not use the truck if there is any damage

or defects.

– Contact your authorised service centre.

7312_003-080

1

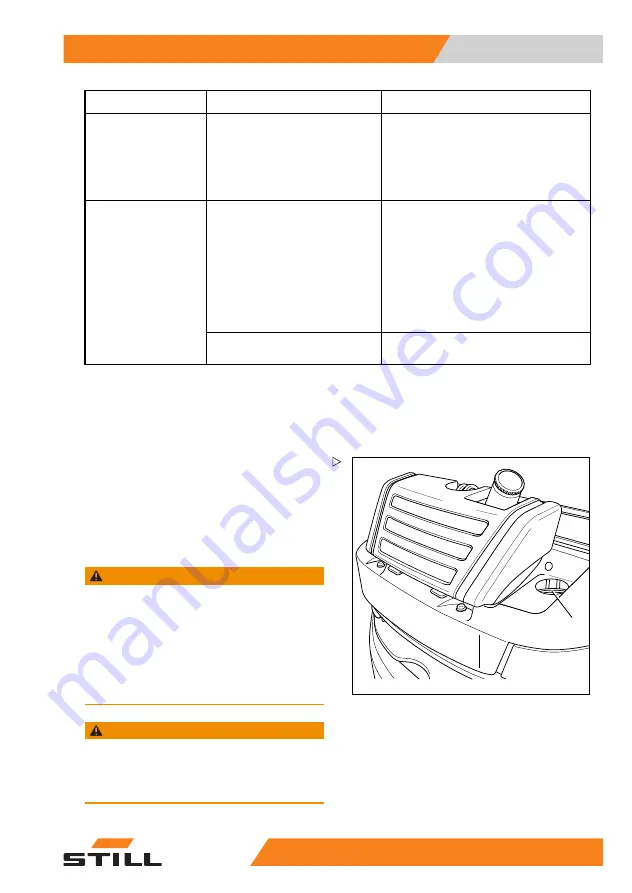

Checking the cooling fluid level

The cooling fluid level is monitored by a

sensor.

As soon as the message

COOLANT LE

-

VEL

appears on the display, proceed as fol-

lows.

WARNING

Risk of scalding due to hot cooling fluid!

The cooling system is pressurised! Opening the

cooling fluid tank may result in hot cooling fluid

leaking out. Only open the cooling fluid tank when

the cooling system is cool.

– Switch off the engine and let it cool down.

– Do not open the cooling fluid tank until the truck

has cooled down.

WARNING

Coolant and cooling fluid can pose a hazard to

health and the environment!

– Observe the safety regulations set out in the

chapter entitled "Coolant and cooling fluid".

– Check coolant level.

174749 EN - 03/2017

71

Summary of Contents for RX70-16

Page 1: ...Original instructions Diesel truck RX70 16 RX70 18 RX70 20 7311 7312 7313 174749 EN 03 2017 ...

Page 2: ......

Page 4: ......

Page 13: ...1 Foreword ...

Page 35: ...2 Safety ...

Page 49: ...Safety 2 Residual risk 174749 EN 03 2017 37 ...

Page 67: ...3 Overviews ...

Page 78: ...3 Overviews Operating and display elements 66 174749 EN 03 2017 ...

Page 79: ...4 Operation ...

Page 310: ...4 Operation Shutdown 298 174749 EN 03 2017 ...

Page 311: ...5 Maintenance ...

Page 318: ...5 Maintenance General maintenance information 306 174749 EN 03 2017 ...

Page 322: ...5 Maintenance General maintenance information 310 174749 EN 03 2017 ...

Page 354: ...5 Maintenance Remaining ready for operation 342 174749 EN 03 2017 ...

Page 359: ...6 Technical data ...

Page 367: ...Technical data 6 Ergonomic dimensions 174749 EN 03 2017 355 ...

Page 378: ......

Page 379: ......

Page 380: ...STILL GmbH 174749 EN 03 2017 ...