5

Maintenance

General maintenance information

Oil and grease types of a different quality

must not be mixed. This negatively affects

the lubricity. If a change between different

manufacturers cannot be avoided, drain the

old oil thoroughly.

Before carrying out lubricating work, filter

changes or any work on the hydraulic system,

carefully clean the area around the part

involved.

When topping up working materials, use only

clean containers!

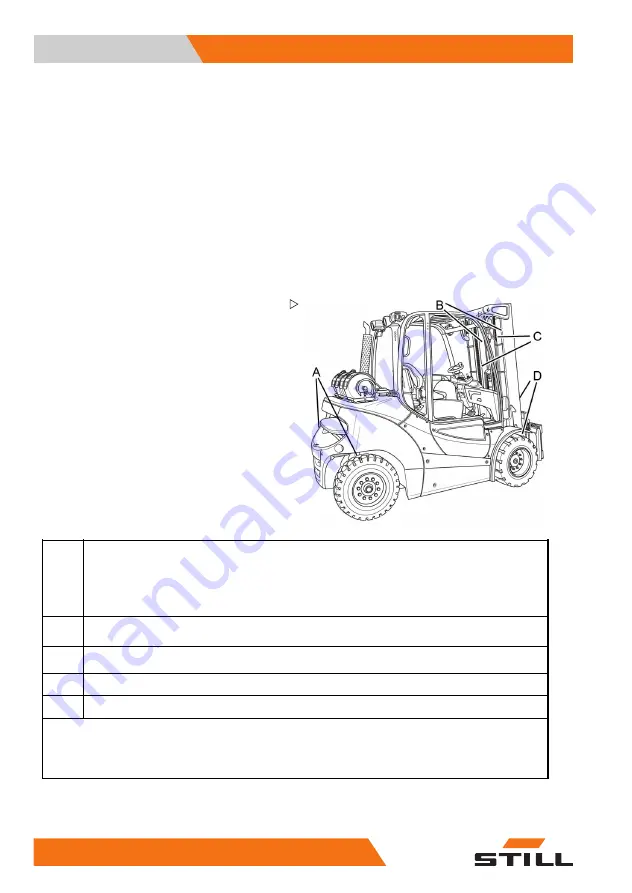

Lubrication plan

Code

1

Lubrication point

(A) Four lubricating nipples on each side of the steering axle for the axle stub bearing and

track rod arm

(B) Sliding surfaces on the lift mast

(C) Load chains

(D) One lubricating nipple each on both lift mast bearings

1

See the following chapter, "Maintenance data table", under this Code.

for the respective lubricant specificationThis lubrication plan describes the series-production

truck with standard equipment. For maintenance points on variant trucks, see the relevant chap-

ter and/or instructions provided by the manufacturer.

.

324

57348011850 EN - 02/2019 - 11

Summary of Contents for RX70-40

Page 2: ......

Page 4: ......

Page 13: ...1 Foreword ...

Page 33: ...2 Safety ...

Page 66: ...2 Safety Emissions 54 57348011850 EN 02 2019 11 ...

Page 67: ...3 Overviews ...

Page 78: ...3 Overviews Operating devices and display elements 66 57348011850 EN 02 2019 11 ...

Page 79: ...4 Operation ...

Page 320: ...4 Operation Decommissioning 308 57348011850 EN 02 2019 11 ...

Page 321: ...5 Maintenance ...

Page 328: ...5 Maintenance General maintenance information 316 57348011850 EN 02 2019 11 ...

Page 332: ...5 Maintenance General maintenance information 320 57348011850 EN 02 2019 11 ...

Page 334: ...5 Maintenance General maintenance information 322 57348011850 EN 02 2019 11 ...

Page 364: ...5 Maintenance Preserving operational readiness 352 57348011850 EN 02 2019 11 ...

Page 371: ...6 Technical data ...

Page 382: ...6 Technical data Fuse assignment 370 57348011850 EN 02 2019 11 ...

Page 391: ......