Operation

4

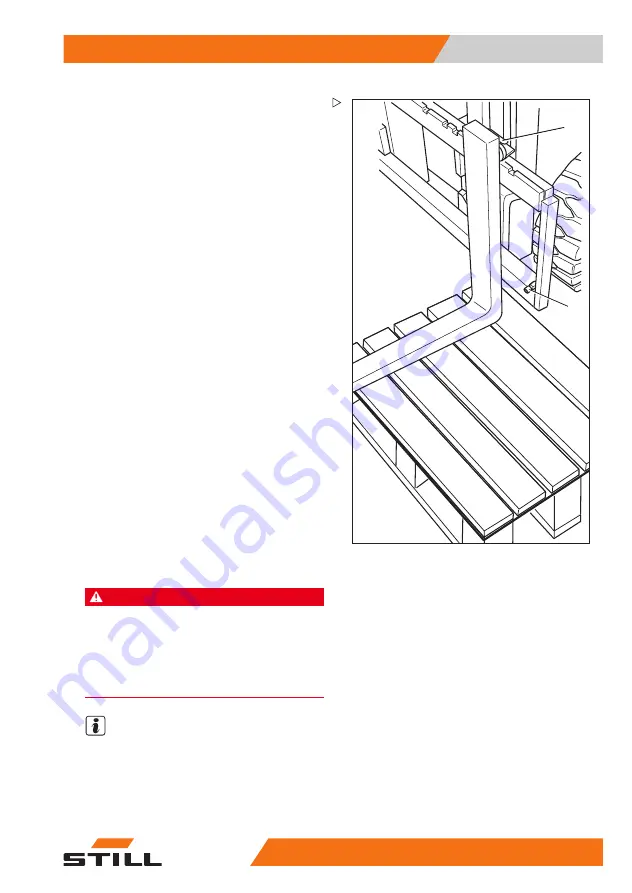

Lifting

1

2

6210_003-027

Removal

– Select a pallet corresponding to the fork arm

size.

– Set down the pallet next to the fork carriage

on the side chosen for removal.

– Lift the fork carriage until the fork arms are

approx. 3 cm above the pallet.

– Apply the parking brake.

– Remove the switch key.

– Unscrew the locking screw (2) on the side

chosen for removal.

– Pull up the locking lever (1) and push the

fork arms onto the pallet one after the other.

Installation

– Make sure that the locking screw is un-

screwed on the side chosen for installation.

– Place the fork arms on a pallet next to

the fork carriage on the side chosen for

installation.

– Pull up the locking lever (1) and push the

fork arms onto the fork carriage one after

the other.

– Place the fork arms in the required position

and push down the locking lever. Ensure

that the locking lever snaps into place.

– Screw in and tighten the locking screw (2).

DANGER

There is a risk of fatal injury from a falling load or

fork!

– Tighten the locking screw each time a fork is

changed.

– Driving and moving loads without the locking

screw is prohibited.

NOTE

If the truck is equipped with the "load measu-

rement" comfort feature, a "zero adjustment of

the load measurement" must always be per-

formed after the fork arms have been chan-

57348011800 EN - 11/2018

161

Summary of Contents for RX70 Series

Page 2: ......

Page 4: ......

Page 13: ...1 Foreword ...

Page 21: ...Foreword 1 Your truck 57348011800 EN 11 2018 9 ...

Page 38: ...1 Foreword Environmental considerations 26 57348011800 EN 11 2018 ...

Page 39: ...2 Safety ...

Page 53: ...Safety 2 Residual risk 57348011800 EN 11 2018 41 ...

Page 71: ...3 Overviews ...

Page 83: ...4 Operation ...

Page 321: ...5 Maintenance ...

Page 328: ...5 Maintenance General maintenance information 316 57348011800 EN 11 2018 ...

Page 330: ...5 Maintenance General maintenance information 318 57348011800 EN 11 2018 ...

Page 334: ...5 Maintenance General maintenance information 322 57348011800 EN 11 2018 ...

Page 378: ...5 Maintenance Remaining ready for operation 366 57348011800 EN 11 2018 ...

Page 379: ...6 1000 hour maintenance annual mainte nance ...

Page 383: ...7 Technical data ...

Page 391: ...Technical data 7 Ergonomic dimensions 57348011800 EN 11 2018 379 ...

Page 394: ...7 Technical data Fuse assignment 382 57348011800 EN 11 2018 ...

Page 404: ......

Page 405: ......

Page 406: ...STILL GmbH 57348011800 EN 11 2018 ...