4

Operation

Procedure in emergencies

– Bend your body against the direction of the

fall.

6321_003-097_V3

1

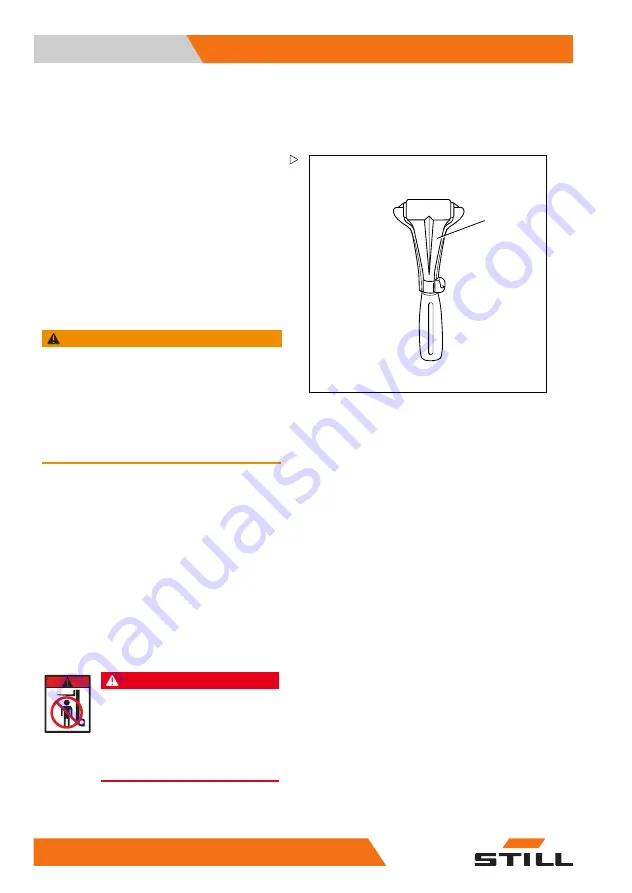

Emergency hammer

The emergency hammer is used to rescue the

driver if he is shut inside the cab in a hazardous

situation, for example if the truck has toppled

over and the cab door cannot be opened.

Single-pane safety glass can be struck rela-

tively safely using the emergency hammer in

order for the driver to escape or be rescued

from the danger area.

Using the emergency hammer

WARNING

When glass is smashed there is a risk of injury

caused by glass splinters!

When the cab glass is smashed, splinters of glass

can shoot into the face and cause damage to skin

and eyes through cuts. When a pane of glass is

smashed, the face should be turned away and

covered with the crook of the free arm.

– Protect the face when smashing a pane of glass.

– Pull the emergency hammer out of its

support mounting at the handle.

– Using one of the two metal tips on the head

of the emergency hammer, hit the pane of

glass with force until it breaks.

Emergency lowering

If the hydraulic controller fails whilst a load

is raised, emergency lowering can be per-

formed. An emergency lowering screw for this

purpose is located on the control block.

DANGER

There is a risk to life from falling

loads or if parts of the truck are being

lowered.

– Do not walk beneath the raised

load.

– Follow the steps described below.

290

57348011800 EN - 11/2018

Summary of Contents for RX70 Series

Page 2: ......

Page 4: ......

Page 13: ...1 Foreword ...

Page 21: ...Foreword 1 Your truck 57348011800 EN 11 2018 9 ...

Page 38: ...1 Foreword Environmental considerations 26 57348011800 EN 11 2018 ...

Page 39: ...2 Safety ...

Page 53: ...Safety 2 Residual risk 57348011800 EN 11 2018 41 ...

Page 71: ...3 Overviews ...

Page 83: ...4 Operation ...

Page 321: ...5 Maintenance ...

Page 328: ...5 Maintenance General maintenance information 316 57348011800 EN 11 2018 ...

Page 330: ...5 Maintenance General maintenance information 318 57348011800 EN 11 2018 ...

Page 334: ...5 Maintenance General maintenance information 322 57348011800 EN 11 2018 ...

Page 378: ...5 Maintenance Remaining ready for operation 366 57348011800 EN 11 2018 ...

Page 379: ...6 1000 hour maintenance annual mainte nance ...

Page 383: ...7 Technical data ...

Page 391: ...Technical data 7 Ergonomic dimensions 57348011800 EN 11 2018 379 ...

Page 394: ...7 Technical data Fuse assignment 382 57348011800 EN 11 2018 ...

Page 404: ......

Page 405: ......

Page 406: ...STILL GmbH 57348011800 EN 11 2018 ...