4

Operation

Attachments

7325_003-050

F1

F1

F2

F2

1

2

Fingertip switch

– To release the clamp locking mechanism,

push the operating lever (1) forwards.

The LED for button

F2

(2) lights up as long as

the clamp locking mechanism is released.

NOTE

The hydraulic function for opening the clamp

is available for one second after the clamp

locking mechanism is released. After one

second, the clamp locking mechanism is

automatically reactivated.

– To open the clamp, push the operating lever

(1) forwards again.

The clamp can be closed without releasing the

clamp locking mechanism.

– To close the clamp, pull the operating lever

(1) backwards.

1

2

3

7090_860-002

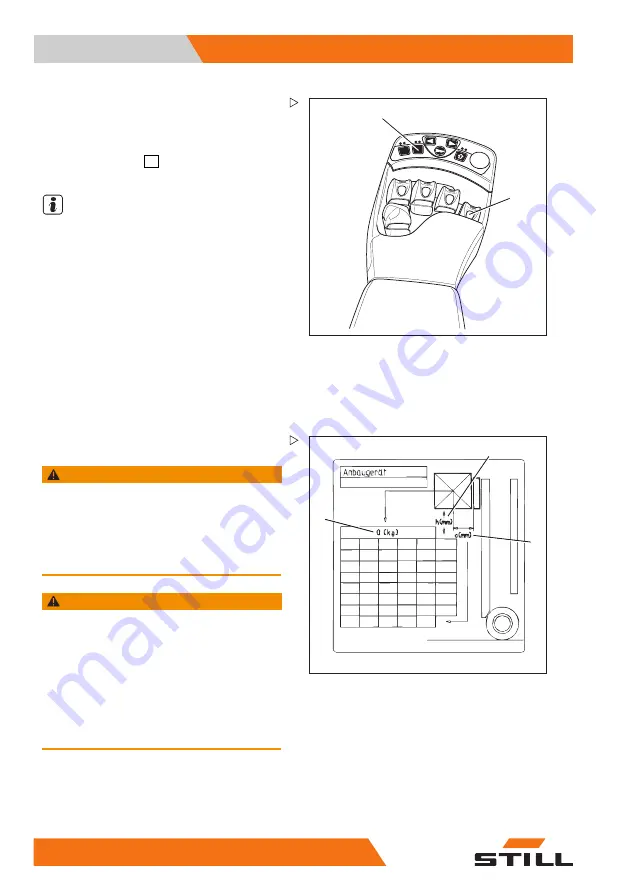

Taking up a load using attachments

WARNING

Risk of accidents!

Attachments may only be used for their intended

purpose as described in the relevant operating

instructions.

Drivers must be instructed in the handling of the

attachments.

WARNING

Risk of accidents!

Loads may only be picked up and transported with

attachments if they are securely attached. Where

necessary, loads should also be secured against

slipping, rolling, falling over, swinging or tipping

over. Note that any change to the position of the

load's centre of gravity will affect the stability of the

forklift truck.

Check the capacity rating plates for the attachments

or combination of attachments.

– The rating plates show the permissible

values for:

216

57348011800 EN - 11/2018

Summary of Contents for RX70 Series

Page 2: ......

Page 4: ......

Page 13: ...1 Foreword ...

Page 21: ...Foreword 1 Your truck 57348011800 EN 11 2018 9 ...

Page 38: ...1 Foreword Environmental considerations 26 57348011800 EN 11 2018 ...

Page 39: ...2 Safety ...

Page 53: ...Safety 2 Residual risk 57348011800 EN 11 2018 41 ...

Page 71: ...3 Overviews ...

Page 83: ...4 Operation ...

Page 321: ...5 Maintenance ...

Page 328: ...5 Maintenance General maintenance information 316 57348011800 EN 11 2018 ...

Page 330: ...5 Maintenance General maintenance information 318 57348011800 EN 11 2018 ...

Page 334: ...5 Maintenance General maintenance information 322 57348011800 EN 11 2018 ...

Page 378: ...5 Maintenance Remaining ready for operation 366 57348011800 EN 11 2018 ...

Page 379: ...6 1000 hour maintenance annual mainte nance ...

Page 383: ...7 Technical data ...

Page 391: ...Technical data 7 Ergonomic dimensions 57348011800 EN 11 2018 379 ...

Page 394: ...7 Technical data Fuse assignment 382 57348011800 EN 11 2018 ...

Page 404: ......

Page 405: ......

Page 406: ...STILL GmbH 57348011800 EN 11 2018 ...