Maintenance

5

Scheduled Maintenance

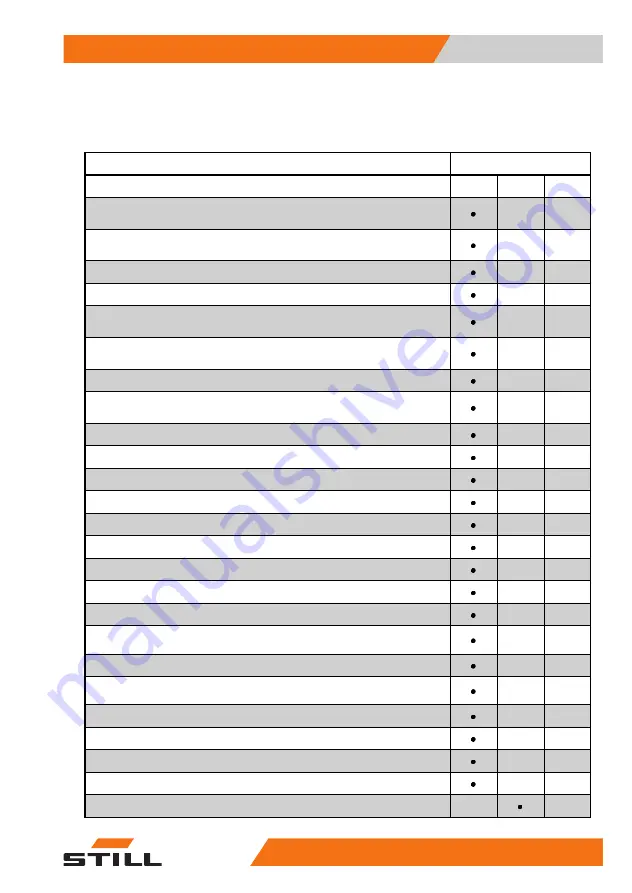

Scheduled Maintenance

Synoptic Table of Maintenance Operations

Operations

Intervals in hours

Further checks

1000

2000

3000

Make sure that the platform adjustment works correctly and locks

properly

Make sure that the seat height adjustment works correctly and locks

properly

Check the fuses

Battery check

Check the condition of the electrical cables and the battery sockets

and make sure they are fastened securely

Check the condition and wear of the wheels and make sure they are

fastened securely

Make sure that the reverse brake works correctly

Make sure that the parking brake and foot brake are correctly adjusted

and working properly

Make sure that the wheel nuts and rims are fastened correctly

Check the condition and wear of the drive wheel

Check for any noises or leaks from the reduction gear

Grease the levers

Check insulation between chassis and any electric motors

Check insulation between chassis and electronic control

Check unions and the condition of the piping

Check hydraulic system oil level

Check reduction gear oil level

Check and adjust front bearings

Lubricate gears

Check the steering and lift motor manifolds

Lubricate platform slide guides

Check wear on the steering motor brushes

Clean the electric steering and lift motors

Lubricate battery compartment rollers

Change reduction gear oil

45418043404 [EN]

57

Summary of Contents for SU-20

Page 1: ...Original instructions SU 20 1610 45418043404 EN 09 2014 ...

Page 2: ......

Page 7: ...1 Introduction ...

Page 17: ...2 Safety ...

Page 28: ...2 Safety Safety tests 22 45418043404 EN ...

Page 29: ...3 Knowledge of the Truck ...

Page 45: ...4 Use and Operation ...

Page 61: ...5 Maintenance ...

Page 77: ...6 Technical data ...

Page 84: ......

Page 85: ......

Page 86: ...STILL GmbH Berzeliusstrasse 10 D 22113 Hamburg Ident no 45418043404 EN ...